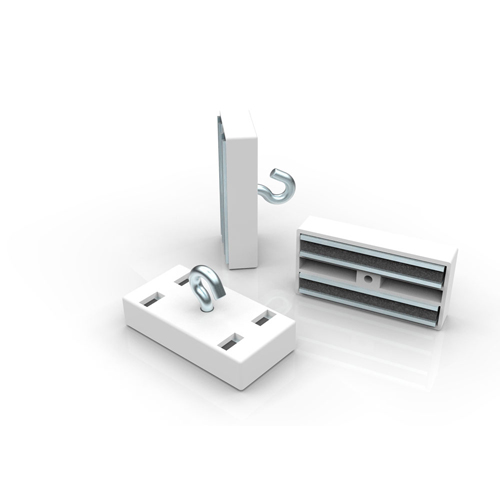

Plastic Cased Magnet with Hook

Descripción del producto

Product Description

These plastic magnetic hooks with elegant white appearance can be fixed on steel ceilings or other steel surfaces for hanging purpose with a decorative effect.

Plastic-cased ferrite hook magnets are also called Magnetic Ceiling Hooks , they are plastic encased ferrite magnet assembly. These ferrite magnets with elegant white appearance can be fixed on steel ceilings or other steel surfaces, for attaching or hanging signs or advertising applications, and they are easily movable to other areas of your store as needed. Great for displaying lightweight signs and products from the ceiling, or even the wall.

Our plastic-cased ferrite hook magnet is 53mm long, 27.5mm wide and 12mm high (28mm high in total with a M4 hook). The magnetic base consists of two ferrite block magnets and four steel plates. These components are divided into pairs in sandwich construction and then inserted into the groove of the plastic case. This optimized construction can help to generate much higher force than block magnets itself.

This plastic-cased ferrite hook magnet uses an open hook design , allowing for easy replacement of signs. It can attach to most metal surfaces, and its vertical holding force is as high as 15KG/147N/33Lbs when test it on a 20mm thick steel sheet at room temperature and then pulling it slowly in vertical direction (Keep in mind that the actual holding force in real application could be different with the change of, for example, pulling direction, thickness and coating of the surface etc.).

Its plastic case is plastic injection molded. Plastic injection molding is the process of melting plastic pellets (thermosetting/ thermoplastic polymers) that once malleable enough, are injected at pressure into a mold cavity, which fills and solidifies to produce the final product.

From left to right, the components of a rapid injection molding press include: ram (1), screw (2), hopper (3), barrel (4), heaters (5), materials (6), nozzle (7), mold (8), and part (9).

Plastic injection molding is an extremely versatile method of producing plastic parts and has multiple advantages over other methods of plastic molding. Not only is the process simpler and more reliable than others methods, but it is also extremely efficient. Backed up with our own plastic injection mold machines in-house, high-quality products with the most competitive prices and short lead time can be ensured.

If you need any kinds of china magnetic assembly, please contact us, as a professional magnetic assembly manufacturer, WEIZHONG is willing to offer you high quality products.