Cross Cylindrical Roller Bearing

제품 설명

Cross cylindrical roller bearings are a type of precision bearing used in applications where high radial and axial loads, as well as tilting moments, are present. They consist of two sets of cylindrical rollers arranged perpendicular to each other and housed within a single outer ring and two inner rings. This configuration allows the bearing to handle both radial and axial loads, as well as tilting moments, with high accuracy and rigidity.

The cross cylindrical roller bearing's unique design allows for high load capacity, high stiffness, and high accuracy, making it suitable for use in machine tools, robotics, and other precision applications. Additionally, the use of rollers instead of balls reduces friction and wear, leading to longer service life and improved reliability.

How to Choose Right Cross Cylindrical Roller Bearing

To select a suitable cross cylindrical bearing, the following requirements must be considered:

Assess the operating conditions, such as the direction of rotation (inner ring or outer ring) and rotational speed, as well as the permissible dimensions for the structure.

Select an appropriate structure based on the required service life, including choosing the proper bearing dimensions, determining the bearing clearance and rigidity, and identifying the appropriate installation location. Additionally, confirm the necessary rotation precision for the application.

Consider the required rotation torque for the application.

Determine the appropriate lubrication method and requirements.

If you are not so sure about the right type of bearing for your application, consult with Thb-bearings. As an expert in bearing, we specializes in providing bearing solutions for different application.

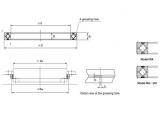

Model RU/RU series

integrated inner and outer ring type,with high rigidity and mounting holes

THB Crossed Cylindrical Roller Bearings Design

The design of a cross cylindrical roller bearing is based on the specific application requirements and load conditions. The following factors are considered in the design process:

Load capacity: The bearing must be able to support the radial and axial loads applied to it.

Rigidity: The bearing should be designed to provide high stiffness and maintain accurate positioning of the rotating components.

Lubrication: Proper lubrication is essential for the smooth operation of the bearing and to prevent wear and damage to the components.

Sealing: The bearing may require sealing to protect against contamination and ensure a long service life.

Cage or isolation block: A cage or isolation block is used to maintain proper roller spacing and prevent roller contact, which can lead to premature wear and failure.

Mounting and dismounting: The bearing should be designed for easy installation and removal, with consideration given to the mounting method and tools required.

Material selection: The components of the bearing, including the inner and outer rings, rollers, cage, and seals, should be made from materials that are suitable for the application environment and can withstand the loads and stresses placed upon them.

The design of a cross-cylindrical roller bearing must balance the requirements for load capacity, rigidity, lubrication, sealing, and ease of mounting and dismounting while ensuring a long service life and reliable performance.

Technical Information of THB Cylindrical Roller Bearings

A cross cylindrical roller bearing typically consists of an inner ring, an outer ring, cylindrical rollers arranged crosswise, and may also include an isolation block or cage to maintain proper roller spacing and prevent roller contact, as well as a seal to protect against contaminants. The cylindrical rollers are arranged in a crossed pattern, which allows the bearing to withstand axial and radial loads from multiple directions. This design provides high precision and rigidity, making it ideal for applications with high rotational speeds and heavy loads.