Ultrasonic Spray Nozzles

Produktbeskrivelse

Ultrasonic nozzle, also known as ultrasonic spray nozzle or ultrasonic spray gun, is an ultrasonic atomization device based on the principle of Langevin transducer. The maximum amplitude of ultrasonic vibration is designed at the front tip of the nozzle. When the liquid is delivered from the rear of the nozzle to the front tip, it is shattered into small droplets by the high-frequency ultrasonic oscillation at the ultrasonic mist nozzle tip to form atomization. Then, the liquid mist can be sent to the substrate or specific space through a certain amount of carrier gas. Under the condition of not exceeding the limit, the liquid atomization amount is only determined by the flow rate of liquid delivery and the operation frequency of the ultrasonic spray nozzle.

Types Of Ultrasonic Spray Nozzles

Focusmist Ultrasonic Nozzle

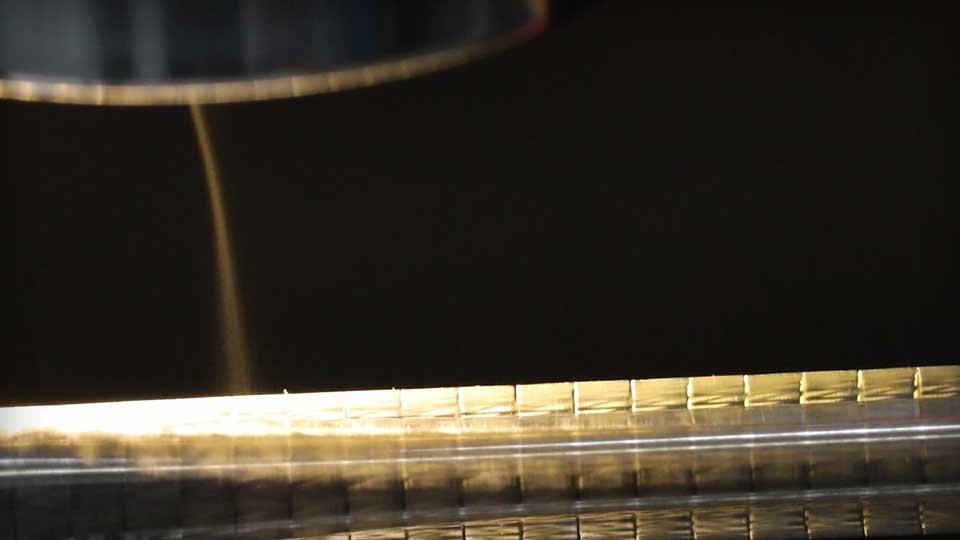

Widemist Ultrasonic Nozzle

Microspray Ultrasonic Nozzles

Conemist Ultrasonic Nozzle

Linemist Ultrasonic Nozzle

Penetrator Ultrasonic Nozzle

Ultrasonic Spray Pyrolysis Nozzle

Ultrasonic Spray Drying Nozzle

How many types of nozzle are there?

There are 8 types with different spray shaping and for different applications of ultrasonic nebulizer transducer nozzles :

WideMist

FocusMist

NanoMist

ConeMist

LineMist

Penetrator

Spray pyrolysis

Spray drying

FAQ of Ultrasonic Spray Nozzles

Which type of ultrasonic spray nozzle is usually used for spray coating?

WideMist ultrasonic nozzle and FocusMist ultrasonic nozzle are most popular model for ultrasonic spray coating application on large area and small area seperately.

In addition, for very small substrates, NanoMist or LineMist ultrasonic nozzle is also usually used.

How do I choose the right nozzle model?

Generally, to determine the right model you need to consider a few main parameters of ultrasonic nozzle such as spray width, flow rate, droplet size, viscosity, etc.

How does ultrasonic spray nozzle work?

The ultrasonic spray nozzle is based on Langevin ultrasonic transducer. A liquid channel is applied in the Langevin ultrasonic transducer.

When the liquid is delivered to the front tip of the transducer horn where has the maximum oscillation amplitude, it is torn by ultrasonic vibration and atomized.

Using Langevin transducer and horn, the oscillation amplitude of the ultrasonic transducer is dramatically improved, so as to increase the maximum atomizable viscosity of liquid, which can reach 30-50 cps.

How Ultrasonic Nozzles Work

Ultrasonic sprayer nozzles, also known as ultrasonic mist nozzles, use high-frequency vibrations to break up a liquid into a fine mist. The nozzle consists of a piezoelectric transducer that converts electrical energy into mechanical vibrations. These vibrations are then transmitted to a metal diaphragm that creates standing waves in the liquid, causing it to atomize into tiny droplets. The size of the droplets can be adjusted by changing the frequency of the vibrations. Ultrasonic nozzles are commonly used in applications such as humidification, coating, and spraying of liquids, as they produce a fine, uniform mist that can be easily controlled.