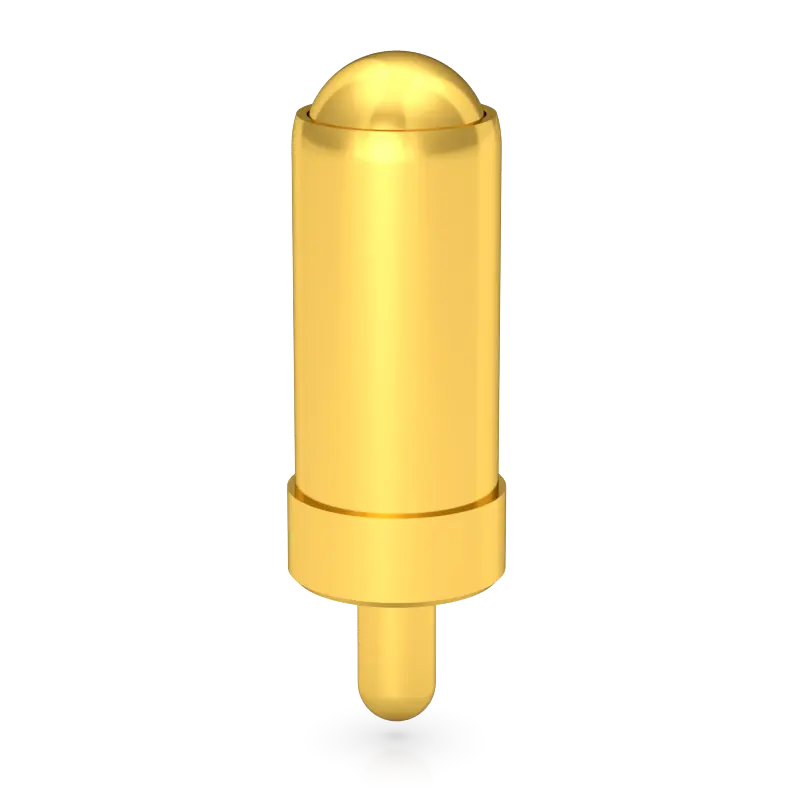

Rolling Ball Pogo Pin

Bidhaa maelezo

Rolling Pogo Pin

Innovative design: Slope Structure Design, More Stable Contact, Lower Resistance

Installation method: SMT Surface Mount (SMD) Reflow Soldering or Placement by Insertion Machine and Fixation by Wave Soldering

Contact Resistance: 30 milliohms Max.

Rated Current: 2A~10A (Continuous Current)

Rated Voltage: 36V AC/DC

Durability: 10,000~100,000 Times (Reciprocating Motion Lifespan)

Operating Temperature: -40°C to +120°C (Continuous Temperature)

Salt Spray Resistance 96 Hours Corrosion Test

High-Precision Mold And Parts Processing

A variety of standards are available, and samples will be sent out as soon as the same day.

Provide Customized Services

Comply With EU RoHS And Reach Standards

Product Details

Rtench Rolling Ball Pogo Pins, also known as pogo pins or Pogo Pin connectors, or Rolling Ball spring-loaded Pins, their core function is to conduct electricity or signal transmission.

The internal design of Rolling Ball Pogo Pins adopts a bevel structure and a built-in spring mechanism. It is mainly composed of four core components: Rolling Ball, Solid Pin, Spring and Body, and is assembled through precision molds and special equipment. The design purpose of the inclined plane structure is to ensure that when the Pogo Pins are working, the lateral force generated by the contact between the inclined plane and the spring is used to push the Rolling Ball to maintain a stable contact force with the inner wall of the Body, so that the current path mainly passes through the gold-plated rolling ball and Body. In order to obtain stable and extremely low contact resistance, a stable and reliable connection can be maintained even under frequent plugging and unplugging.

How to install Rolling Ball Pogo Pins:

SMT automatic patch reflow technology: The SMT automatic patch machine automatically mounts Rolling Ball Pogo Pins onto the PCB circuit board with solder paste printed on it. The solder pins are accurately inserted into the PCB circuit board holes, and then the tin is made through the reflow soldering process. The paste melts and solidifies, completing the fixed connection to the PCB pad. This process is fast, accurate and highly automated, greatly improving production efficiency and product quality.

Plug-in machine + wave soldering technology: The automatic plug-in machine automatically mounts the Rolling Ball Pogo Pins and accurately inserts the solder pins into the PCB circuit board with printed solder paste, and then melts and fixes the solder paste through the wave soldering process to complete the Fixed connection to PCB pads. The process is fast, accurate and highly automated, greatly improving production efficiency and product quality. This method is particularly suitable for electronic components with extremely long solder legs that cannot be fixed through SMD reflow soldering.

Material & Parts

Rolling Ball Pogo Pins are one of the categories of Pogo Pin Connectors, Vertical Contact type and Side Contact type. This is a built-in spring connector based on a bevel structure design and consists of four core components: Rolling Ball, SolidPin, Spring and Body. Its unique feature is that its contact surface is a gold-plated ball that can rotate 360 degrees, which greatly reduces the wear of the contact surface. Due to its extremely low resistance, its connection is stable and reliable, resulting in long life and durability.

rolling pogo pin material

The internal structure of Rolling Ball Pogo Pins adopts a ball + bevel structure, which ensures stable and reliable contact between the ball and the inside of the needle tube.

rolling pogo pin structure

Contact force and contact resistance are key factors to ensure a stable and reliable connection. There is a close relationship between the two: increasing contact force can effectively reduce contact resistance. Therefore, achieving stable contact force and contact resistance is an important step in establishing a reliable connection.