Coil Upender For Sale

Ürün tanımı

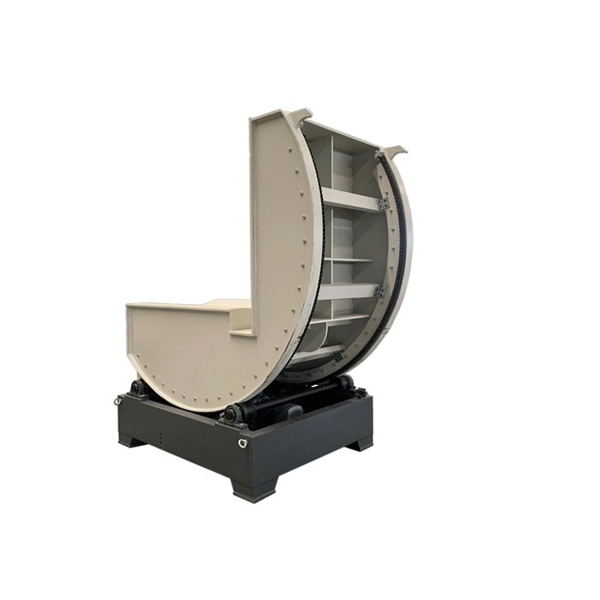

Coil Upender For Sale

A Coil Upender, also known as a coil tilter or coil tipper, is a specialized piece of equipment used in various industrial settings to safely and efficiently rotate heavy coils of metal, wire, or other materials from a horizontal to a vertical position, or vice versa.

Types of Coil Upender

We have 8T and 10T coil upender machine for the users to choose and both of them are electric motor driven coil unpenders. Key Features and Specifications:

1. Capacity: Coil upenders come in various capacitie. It’s crucial to choose an upender that can handle the maximum weight of your coils.

2. Size Compatibility: Ensure the upender can accommodate the diameter and width of your coils.

3. Rotation Mechanism: Use electric systems to rotate the coil.

4. Safety Features: Look for features such as safety locks, emergency stop buttons, and secure holding mechanisms to ensure safe operation.

5. Control Systems: There's remote controls and programmable settings for precise operation.

6. Construction Material: High-quality steel construction is common for durability and long service life.

8T Coil Upender

An 8T coil upender, also known as a coil tilter machine or coil tipper, is a specialized piece of industrial equipment designed to safely and efficiently rotate heavy metal coils from a horizontal to a vertical position or vice versa.

10T Coil Upender

They are typically used in conjunction with other material handling equipment, such as cranes and forklifts, to move and position coils.

Installation and Debugging Methods of Coil Upender

Installing and debugging a coil upender involves several steps to ensure it operates correctly and safely. Below is a general guide to help you through the process:

Installation Steps

Site Preparation

Location: Choose a flat, stable surface that can support the weight of the upender and the coils.

Space: Ensure there is enough space around the upender for safe operation and maintenance.

Power Supply: Verify that the power supply meets the upender’s requirements (voltage, phase, and frequency).

Electrical Connections

Power Connection: Connect the upender to the power supply. Ensure all electrical connections are secure and meet local electrical codes.

Control Panel: Connect the control panel or remote control.

Safety Checks

Emergency Stops: Verify that all emergency stop buttons are functional.

Safety Guards: Ensure all safety guards and barriers are in place and secure.

Warning Labels: Check that all warning labels are visible and legible.

Debugging Steps

Initial Power-Up

Turn On: Power up the upender and observe for any immediate issues such as unusual noises or error messages.

Control Check: Test the control panel to ensure all buttons and switches are functioning correctly.

Safety System Test

Emergency Stops: Test all emergency stop buttons to ensure they immediately halt the operation.

Safety Guards: Verify that safety guards are functioning and that the upender stops if a guard is breached.

Safe Operating Procedure of Coil Upender

A proper and safe operating procedure of running a coil upender is very important.

Ensure the area around the upender is clear of obstructions.

Verify that the coil to be upended is within the weight and size limits of the upender.

Use appropriate lifting equipment to position the coil on the upender.

Loading the Coil

Position the coil securely on the upender’s platform.

Ensure the coil is centered and stable.

Use any provided securing mechanisms to hold the coil in place.

Starting the Upender

Turn on the power supply to the upender.