Aromatic Hydrocarbons

Penerangan produk

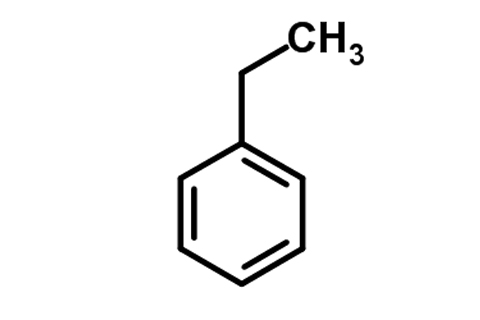

Aromatic hydrocarbons are the collective name for benzene and its carbon and hydrogen-only derivatives, which are hydrocarbon compounds with one or more benzene rings in their molecular structure. The simplest and most important aromatic hydrocarbons are benzene and its congeners toluene, xylene, ethylbenzene, etc.

AROMATIC HYDROCARBONS BENEFITS

Aromatic hydrocarbons, also known as arenes, have several benefits including:

Fuel: Aromatic hydrocarbons are used as fuel additives, due to their high energy density and low volatility.

Solvents: They are widely used as solvents in various industrial processes, due to their non-reactivity and low toxicity.

Intermediates: Aromatic hydrocarbons are used as intermediates in the synthesis of a variety of chemicals such as pharmaceuticals, dyes, and plastics.

Aroma: Aromatic hydrocarbons are also used in perfumes, fragrances, and flavors, due to their pleasant aroma.

Pesticides: Some aromatic hydrocarbons, such as pyrethroids, are used as insecticides and pesticides.

AROMATIC HYDROCARBONS PRODUCTION

Aromatic hydrocarbons are a class of organic compounds that contain one or more aromatic rings, such as benzene, toluene, and xylene. These compounds are widely used as raw materials in the production of various chemicals and plastics, such as polyethylene terephthalate (PET) and polyurethane.

The production of aromatic hydrocarbons typically involves two main processes: extraction and refining. In the extraction process, crude oil or natural gas is processed to extract the desired hydrocarbons, including aromatics. This process involves fractional distillation, in which the different hydrocarbons are separated based on their boiling points.

Once the aromatics are extracted, they undergo a refining process to remove impurities and convert them into the desired products. This refining process may involve various techniques, such as catalytic reforming, which converts naphtha into higher-octane aromatics; alkylation, which combines smaller molecules to form larger ones; and transalkylation, which converts alkylated aromatics into the desired product.

The production of aromatic hydrocarbons is a complex process that requires specialized equipment and expertise. The use of advanced technologies, such as catalysts and process control systems, has enabled manufacturers to produce high-quality aromatics efficiently and cost-effectively.

In addition to their use as raw materials in the production of chemicals and plastics, aromatic hydrocarbons are also used as solvents, fuels, and intermediates in the manufacture of pharmaceuticals and other products. They play a vital role in many industries and are essential in modern society.

WHY CHOOSE TOPFINE AROMATIC HYDROCARBONS

producing high-quality aromatic hydrocarbons that meet strict industry standards and customer requirements.

Competitive pricing: TOPFINE may offer competitive pricing for their aromatic hydrocarbon products, ensuring that customers receive good value for their investment.

Excellent customer service: TOPFINE may prioritize providing excellent customer service and support, ensuring that their customers' needs are met and questions are answered in a timely and helpful manner.

Expertise:

TOPFINE may have extensive experience and knowledge in the production and supply of aromatic hydrocarbons, which enables them to provide tailored solutions to meet specific customer needs.

Reliability: Customers may trust TOPFINE to consistently provide reliable and timely delivery of their products.

Customization: TOPFINE may be able to provide customized products and solutions to meet the unique requirements of their customers.

AROMATIC HYDROCARBONS APPLICATIONS

Aromatic hydrocarbons have a wide range of applications in various industries. Some of the common applications of these compounds are:

Production of fragrances and flavors:

Aromatic hydrocarbons are used as key ingredients in the production of fragrances and flavors.