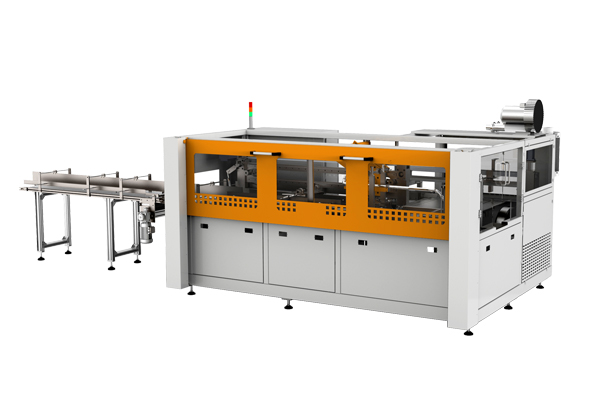

Automatic Multi Rolls Toilet Paper Bundling Packing Machine ZB680F

产品说明

Specification of Toilet Roll Bundler Machine

Model number ZB680F

Average Speed 20-25bundles/min

Packing type 4.6.8.10.12 rolls

Finished bundle size 690*(160-260)*(90-125)mm (L*W*H)

Bag material PE Pre-made bag

Packing film thickness 40-65μm

Pre-made bag stock 2 bag stocks, automatically change

Machine size 8640×2830×1800mm(L×W×H)

Whole power 14.8kw

Power supply 380V 50HZ

Air consuming 0.5~0.7Mpa ,air usage: 350L/min

Weight Around 4000kg

Noise ≤80 dB

If you are interested in this paper bundling machine, leave us a message and get the tissue paper packing machine price.

Main Features of Bundle Paper Rolls Packing Machine

This series of tissue paper soontrue packaging machines are suitable for packing tissue rolls in a bundle. These paper bundle packing machines are suitable for packing bundling rolls (6,8,10,12 toilet roll bundles in one bag). In addition, this type of toilet paper wrapping machine can also be connected with a log saw machine or a single roll wrapping machine.

This series of paper bundling machines are equipped with an automatic tissue arranging system to make the specification changing faster and the space inside the machine is very convenient for maintenance.

Capable of conveying the bags precisely, this toilet paper roll bundle machine will alarm or stop if there are no bags.

The tissues will be automatically removed during the abnormal stop of these bundle packaging machines. In addition, the waste film will be automatically collected by these paper toilet paper roll machines and if the waste film got stuck, the paper roll machine will automatically alarm or stop.

Lastly, this automatic roll packing machine also has the function of overload protection (the machine will be stopped when it is overload). When it comes to this kind of situation, you can simply reset the overload device and press the reset button to make the servo control system automatically back to its origin (slowly).