Engineering

Tjänstebeskrivning

RAS employs a full engineering team to specifically design and manage the production of conveyor pulleys. Each pulley is run though our P-Flex software program that tells us in real time whether the pulley will hold up to the belt tensions and load placed upon it. We design all our pulleys following our in house flexible design methodology to ensure your pulleys are designed for infinite life.

Antapaccay Direct Drive Pulley

RAS is world renowned for solving difficult conveyor problems which has enabled us to supply pulleys to projects where reliability is paramount. RAS was tasked in 2010 to build the pulleys for the world’s second ever gear-less direct drive application at Xstrata’s Antapaccay Copper project in Peru. RAS engineered the gear-less direct drive pulleys (pictured right) used in this application, designed to withstand 1,422 kN of tension and 3720 kW of power.

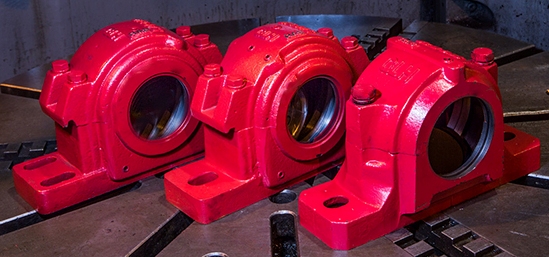

The Alberta Oil-sands is another area where RAS engineering expertise has helped solve issues with abrasive materials, large temperature swings and extreme working conditions. RAS has developed solutions to increase pulley life by over 100% and is continually working to improve the reliability in the area.