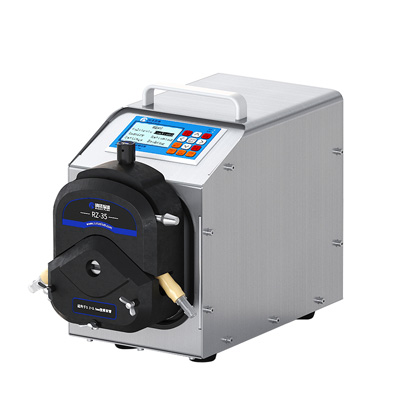

Laboratory Peristaltic Pump

Penerangan produk

Laboratory liquid pump is a bench-top type peristaltic liquid pump suitable for laboratories and production line to filling bottles or fluid metering, the LCD screen shows the detailed status of working such as flow rate, speed, flow direction, filling times etc., it included 4 working modes of booking, calibration, metering and continuous for a wide application needs. High cost performance makes it very popular in lab or beverage filling production line.

Advantages of Lab Peristaltic Pump

High Quality Materials Selection

RUNZE lab liquid pump are made of engineering plastics like ABS and PC with high strength for industrial use, rollers are made of stainless steels to extend the service life, they are workable for non-corrosive friendly environment. LCD screen is very clear to show all the working parameters.

High Stability Structure Design

Laboratory peristaltic pumps are equipped with 3 roller, 4 rollers, 6 rollers to meet different flow rate and pulsation requirements, most of them are very easy to open and close to replace peristaltic tubing, flexible upper blocks are receiving different tube sizes for different flow ranges. Drive systems are very smart to realize complex processing steps.

Flexible Application Modes

Laboratory peristaltic pump are able to work in flexible working modes such as booking, calibration, metering and continuous for flexible application requirements. External foot pedal and communication interface are available to some users who need them, it included very wide application configurations.

Applications of Laboratory Peristaltic Pump

Lab peristaltic pumps are one of the important components in lab, medical and production line. Liquid only touch medical grade tubes without any cross contaminations between pumps and fluids. This type of fluid control equipment is widely used in environmental analyzers, laboratory instrument, medical equipment, petrochemical systems, food and beverage vending machine, bio-pharmaceuticals analysis and metering. High stability is the most important factor, quality materials, high quality molding and machining make these realized.

If you want to know more kinds of fluid control equipment, please visit our website.