Molybdenum Target

Product description

The requirements for molybdenum targets are significantly more stringent than those of conventional material industries. These requirements entail aspects including size, flatness, purity, content of impurities, density, N/O/C/S levels, grain size, and defect control. Even more rigorous or specialized requirements include surface roughness, resistance values, uniformity of grain size, composition and microstructure, foreign matter (oxide) content and size, magnetic permeability, ultra-high density, ultra-fine grains, among others.

Molybdenum sputtering coating is a newly developed physical vapor deposition technique that utilizes an electron gun system to focus and emit electrons onto the plated material. By following the momentum exchange principle, atoms are ejected out of the target surface with high kinetic energy and settle onto the substrate to form a film. The material used for the plating process is called sputtering target, which can be made from different materials such as metals, alloys, and ceramic compounds.

Types of Molybdenum Target

Planar Molybdenum Target

Purity: 99.95%

Density: ≥ 10.2 g/cm3

Size range: Customization available as required

Appearance: Microscopic examination shows the surface with uniform metallic luster, without oxidation/hydrogenation discoloration, scratches, deformation, burrs, etc.

Application: It is used to make heating parts and heat insulation parts for vacuum heat treating furnace, and to produce digesters, heaters, coolers, various utensils and devices in chemical industry. It is also extensively applied in aerospace industry, medical instruments and other fields. The sputtering target is used for magnetron sputtering coating, which is a newly developed physical vapor deposition (PVD) method.

Planar Molybdenum Target

Rotatory Molybdenum Target

Rotatory target is a kind of sputtering target. The target is made into a cylindrical shape, which is equipped with a stationary magnet inside to achieve rotatory coating at a slow speed.

We can provide molybdenum sputtering targets of the following sizes as required: length ≤ 165 mm X1000 mm, purity ≥ 99.95%.

Application: Solar cell, architectural glass, automobile glass, semiconductor, flat panel TV, etc.

Rotatory Molybdenum Target

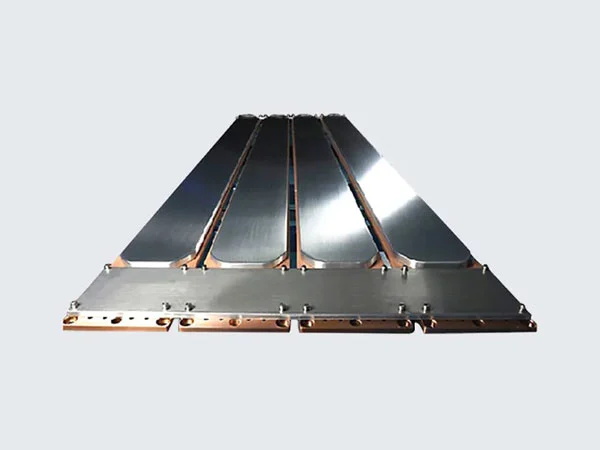

Wide Molybdenum Target

High-purity wide molybdenum target is one of the key raw materials in the production of AMOLED panel. Our products include ultra-wide, high-purity and high-density planar molybdenum sputtering targets suitable for TFT-LCD/AMOLED, which are mainly used in G2.5-G6 generation TFT-LCD/AMOLED, thereby filling the gap of wide molybdenum target (1800 mm) in China market.

Wide Molybdenum Target

Operating Principle of Molybdenum Target

Molybdenum targets are used in the production of thin films through the process of magnetron sputtering. This process involves bombarding a metallic target with high-energy ions, which eject atoms from the target surface. These ejected atoms then deposit onto a substrate to form a thin film.