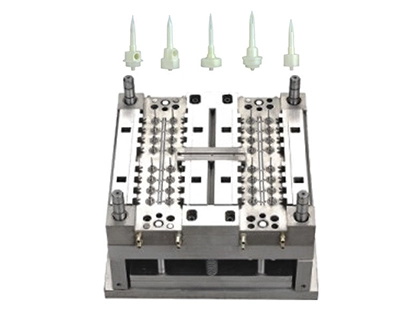

INFUSION SET SPIKE MOLD

وصف المنتج

INFUSION SET SPIKE MOLD

The Infusion Set Spike Mould is a medical device used in the production of spike components for infusion sets. The mold is made of high-quality stainless steel and designed to produce spike components with precise dimensions and smooth surfaces for reliable and comfortable delivery of fluids or drugs to patients.

The mold comes in various sizes to suit different infusion set spike designs and is compatible with various types of injection molding machines. Its unique design and technology enable the production of multiple spike components in one injection cycle, increasing efficiency and reducing manufacturing costs.

LINKPLUS's Infusion Set Spike Mold is easy to use and maintain, and comes with detailed instructions for sterilization and cleaning to ensure proper hygiene and longevity. The mold is also compatible with a range of materials, making it versatile and suitable for various applications.

HOW DOES AN INFUSION SET SPIKE MOLD WORK?

An infusion set spike mold works by injecting liquid plastic material into the mold's cavity under high pressure. This process is known as injection molding. The mold is designed with a specific shape that will determine the final form of the infusion set spike. Once the plastic material is injected, it cools and solidifies, forming the spike's final shape. The completed infusion set spike is then removed from the mold, and the mold is cleaned and prepared for the next production cycle. This process allows for precise and consistent production of infusion set spikes, ensuring they meet the required standards for medical use.

HOW DO YOU MAINTAIN AN INFUSION SET SPIKE MOLD?

Proper maintenance of an infusion set spike mold is essential for its optimal performance and longevity. Below are some tips for maintaining an infusion set spike mold:

Keep the mold clean: Regular cleaning of the mold is essential to prevent plastic material buildup, which can affect the quality of the infusion set spikes. Use a dry cloth, brush, or air blast to remove any debris or residue from the mold.

Lubricate the moving parts: Lubricating the mold's moving parts, such as the ejector pins and guide pins, helps to prevent wear and tear and ensures smooth operation. Apply a small amount of oil or grease to these parts as per the manufacturer's instructions.

Inspect the mold for damages: Routine inspections of the mold are necessary to detect any signs of wear, cracks or deformations. Address any identified issues promptly to avoid further damage or deterioration.

Store the mold properly: The mold should be stored in a dry, clean environment, free from dust and other contaminants. Proper storage conditions help to prevent rusting, corrosion or other types of damage.

As a medical molding manufacturer, we will do our best to meet all the needs of customers.