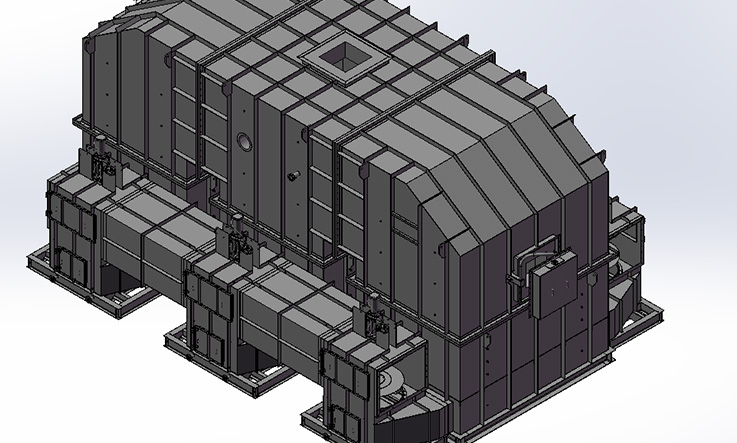

Regenerative Thermal Oxidizer (RTO)

Produktbeskrivelse

Regenerative Thermal Oxidizer (RTO) produced by regenerative thermal oxidizer manufacturers which uses ceramic media to recover upwards of 97% of the available energy and is widely considered to be the most energy-efficient oxidizer. Its ability to repurpose the thermal energy generated during operation to reduce operating costs and energy consumption of the system itself make the RTO so popular widely. The regenerative component makes regenerative thermal oxidiser capable of fuel-free operation at very low VOC concentrations.

Benefits of the RTO Oxidizer

System pressure drop resulting in reduced electrical consumption

Multiple designs for easier and faster installation

Regenerative thermal oxidizer(RTO) has greater system flexibility and versatility

High reliability and long-life expectancy (15-20 years+)

Design Features of RTO Oxidizer

Pre-assembly, wiring, and testing as much as possible prior to shipment

Regenerative thermal oxidation can apply in the process of flowing up to 25% Lower Explosive Limits (LEL) with self-sustaining LELs as low as 3%

The burner is sized for full flow, zero process VOC emissions so that the RTO can maintain temperature and VOC destruction efficiency over the entire range of process operation.