INDUSTRIAL FILTER

產品說明

Industrial centrifugal type filter, centrifugal separator filter is the pressurization rotary drum filter, integrating washing, extracting, evaporating, and drying is a piece of closed equipment that realizes solid-liquid separation after continuously and automatically retaining the solid granules in the liquid and solid mixture by using porous rotary drum filtering media.

01

YG Rotary Drum Filter

The pressurization rotary drum centrifugal filter separator, integrating washing, extracting, evaporating and drying, is a piece of closed equipment that realizes solid-liquid separation after continuously and automatically retaining the solid granules in the liquid and solid mixture by using porous rotary drum filtering media.

02

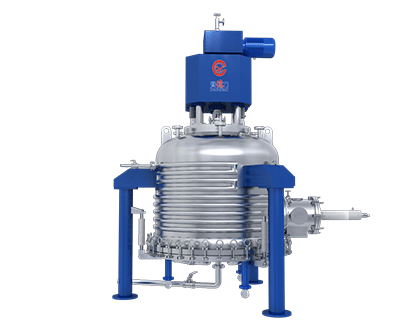

Nutsche Filter

Nutsche multiple function filtering washing and drying facility (three in one) can finish a series of processes such as stirring, reaction, filtering, washing, dehydration and drying(repulping can also be processed), etc. With its simple structure and simplified working process, it has a higher efficiency, easier exchanging of product and good performance of automation without any cross-contamination. Meanwhile, cleaning plant building and basic investing fee can be reduced.

Industrial Filter

YG Rotary Drum Filter

Nutsche Filter

HOW DOES SAIDELI'S INDUSTRIAL FILTER WORK?

The main functions of the centrifugal filter devices are washing, filtering, and drying. The washing process of centrifugal filter, centrifugal filter unit is accomplished by spraying the washing liquid with a spray ball or a cleaning ring set on the top head. Filtration is mainly accomplished by the filter screen or cloth on the chassis, and the porous plate flange and the porous plate filter disc are installed on the body to seal. The function of the drying part is realized by a heating system of semi-circular coil or integral jacket, bottom coil or jacket and agitator. When drying, hot water or steam can be injected into a semi-circular jacket and agitator.

As one of an industrial centrifuge manufacturers, we have high quality centrifugal separation equipment for sale, if you have any need, please contact us.