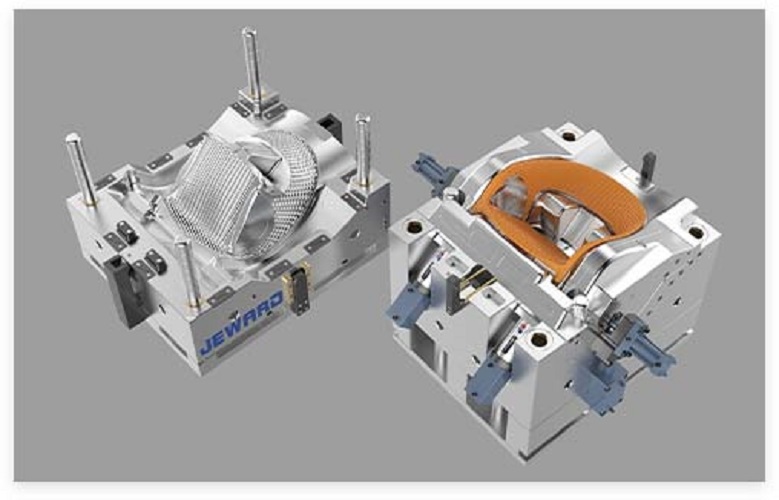

JEWARD PLASTIC INJECTION MOULD

தயாரிப்பு விளக்கம்

Among the three key elements of injection molding industry, material, machine and mould, the plastic injection mould is the most important and changeable one. It brings countless changes to plastic products. And because of the variety of products, processes and materials, the mould itself also develops many different structures. Jeward Mould, as an experienced company that makes plastic molds, could adopt different mould technologies to produce custom injection molded products, which are suitable for various industries and processes.

Different types of injection moulds for sale

Jeward Mould offers various types of injection molds including chair & sofa mold, houseware mold, crate & pallet mold, packing mold, cabinet & drawer mold, waste bin mold, flower pot mold, tool box & DIY mold, table & stool mold, blow mold and ready mold. We could produce molds in various styles and materials according to customers’ demands and provide helpful suggestions that we gained from our experience. If you are interested in the products not listed below, please feel free to contact us and get more information!

THE ADVANTAGE OF JEWARD MOULD FOR PLASTIC INJECTION MOLDING PROCESS

As a plastic molding die maker with lots of clients from all over the world, Jeward Mould equips with an experienced and professional engineer team. We are familiar with the plastic injection molding process, so we could fully communicate the technical problems with customers during the mould design process. We will ensure our plastic mould products cooperate smoothly with customers' main and auxiliary engines including injection molding machine, robotic, water chiller, etc. Also, we, a plastic injection mold maker in china, take the plastic material and injection technology requirement into consideration, to guarantee our custom injection molded products operate effectively and steadily in the plastic injection molding process in our customers' factories.