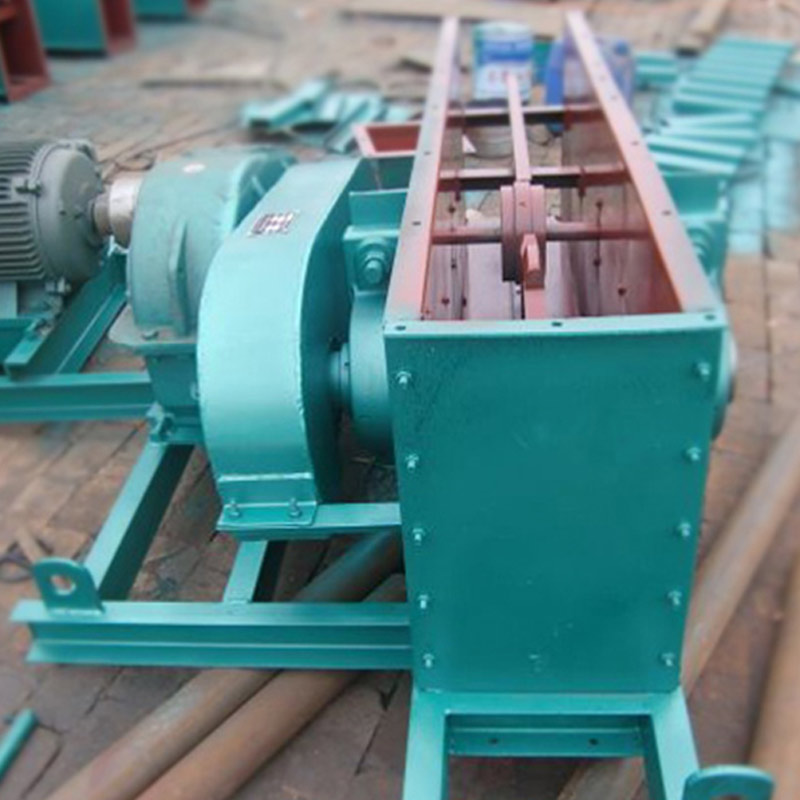

Scraper Conveyor

ఉత్పత్తి వివరణ

With a squeegee chain traction, the conveyor that transports the bulk material in the tank is called a scraper conveyor. The adjacent middle slot can be flexibly limited in the horizontal and vertical planes. The face conveyor where the fuselage is bent at a 90-degree angle at the intersection of the work surface and the transportation lane is called a "corner scraper conveyor".

In the current coal mining face, the role of scraper conveyor is not only to transport coal and materials, but also the operating track of the coal mining machine, so scraper conveyor has become indispensable main equipment in modern coal mining technology. The coal scraper conveyor can keep running continuously and production can be performed normally. Otherwise, the entire coal mining face will show a state of discontinued production and disrupt the entire production.

The main structure and components of various types of scraper conveyors are basically the same. The scraper conveyor consists of three parts: nose, middle and tail. In addition, there are auxiliary components such as a hydraulic jack device for moving the conveyor and a chain tensioner for tightening the chain. The head of the machine is composed of the headstock, electric motor, fluid coupling, reducer and sprocket. The middle part of the scraper conveyor consists of transition slots, middle slots, chains, and scrapers. The tail of the scraper conveyor is the device for the scraper chain return. Like the nose, the tail end of the heavy-duty scraper conveyor is also provided with a power transmission device to distinguish the upper head from the lower head from the installed position.

Conveyor Scraper System Classifications

According to the arrangement and structure of the chute conveyor chute, scraper conveyor can be divided into two types: parallel chain and overlapping type. According to the number of chain and arrangement of scraper conveyor, it can be divided into single chain, double chain, double center chain and three chains.

Working Principle Of Scraper Conveyor

The working principle of the scraper conveyor is that the open chute is used as a bearing member for coal, vermiculite, or materials, and the scraper is fixed on the chain (composed of a scraper chain) as a traction member. When the head drive section of the scraper conveyor is started, the sprocket on the motive head shaft rotates, causing the scraper chain to cycle and move the animal material along the chute until the head of the machine is unloaded. The scraper chain bypasses the sprocket for strapless, closed-loop operation to complete the material transfer. As one of scraper conveyor suppliers , Senotay can help you with conveying materials effectively by our wholesale scraper conveyor at low prices. Contact us!

Wholesale Scraper Conveyor Advantages

Well designed by Senotay, an experienced conveyor belt scraper supplier, our scraper conveyor system has the following advantages.

Senotay scraper conveyor has a solid structure, which can withstand the impact of coal, vermiculite or other materials, impact, collision, pressure, pressure and other external forces.

Senotay scraper conveyor can adapt to the need of the coal mining working face to be uneven and curved and can withstand vertical or horizontal bending.

Senotay scraper conveyor has a short body and is easy to install.

Senotay scraper conveyor can double as the orbit of the shearer.

Senotay scraper conveyor can run in reverse, easy to handle the bottom chain accident.

Senotay scraper conveyor can be used as the fulcrum of the front section of the hydraulic support.

The structure of our scraper conveyor is simple, in the length of the conveyor can be fed or unloaded at any point.

The enclosure is closed, which can prevent dust from flying and contaminate the environment when materials are transported.

When the tail does not set the shell, and insert the scraper into the stack, you can take the material delivery.

Wholesale Scraper Conveyor Disadvantag