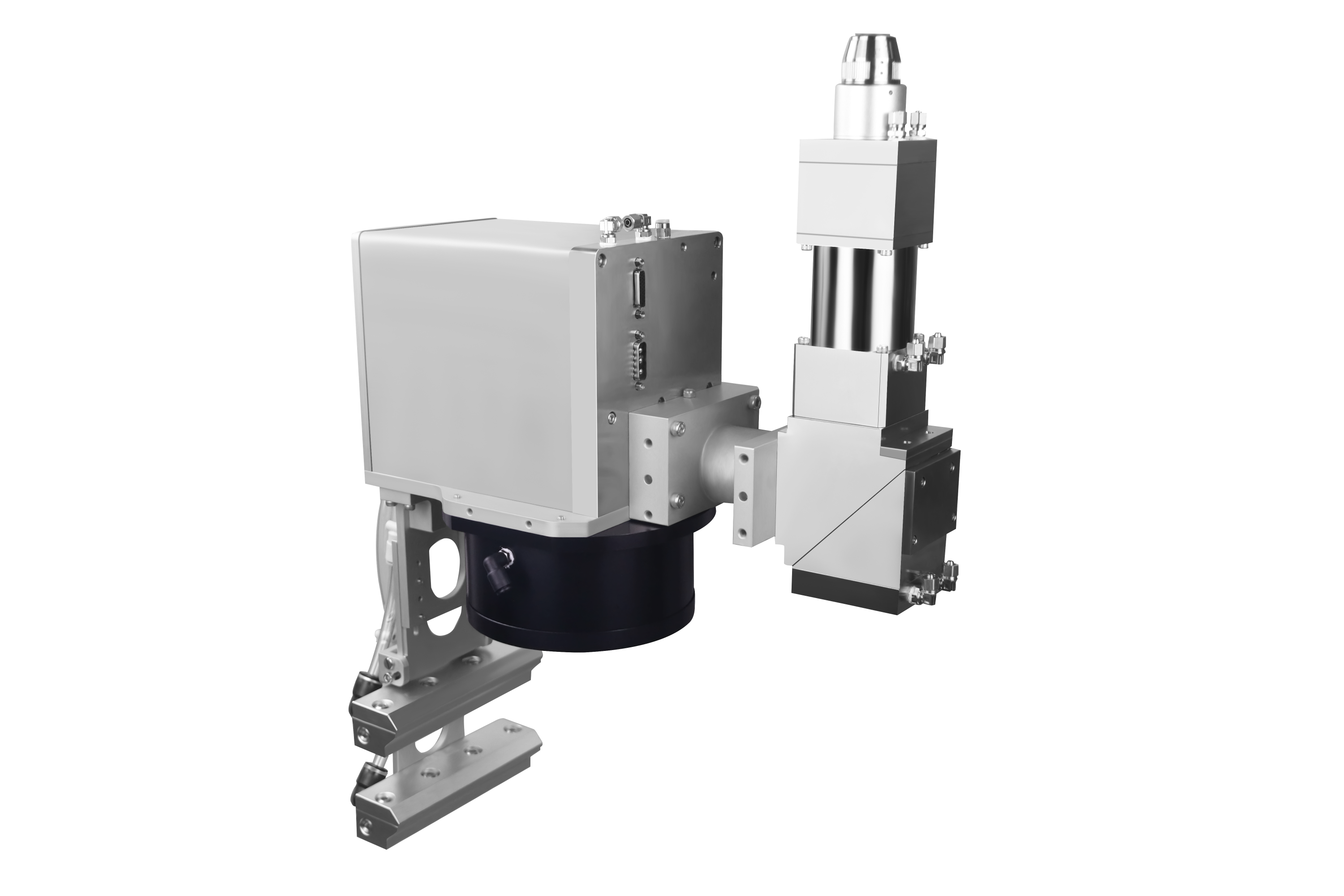

High Power Galvanometer Welding System

Penerangan produk

High power galvo laser welding system is independently developed by Scanner Optics. The system after fully validated, with carefully designed double wind cooling water circulation system and excellent whole sealing, strict selection and testing of optical element, the assembly process, can be in 6KW laser power work stably for a long time. High power laser welding system consists of high power galvanometer and control cabinet. The high power galvanometer system consists of a galvanometer, collimation, connection, red light indicator system and auxiliary accessories. Now it is mainly used in lithium battery welding industry, automobile welding, consumer electronics, hardware processing, aerospace and other industries.

Features of Galvo Laser Welding System

High Precision Scanning: Utilizes galvanometer-based scanning systems for rapid and precise laser beam positioning.

Fast Processing Speed: Enables high-speed galvo laser welding operations due to the quick and accurate movement of the laser beam.

Versatility in Materials: Suitable for welding a wide range of materials, including metals, alloys, and plastics.

Fine Control and Resolution: Provides fine control over the laser beam, resulting in high-resolution welds with minimal heat-affected zones.

Automated Processing: Supports automated and programmable laser welding galvanometer processes, enhancing efficiency and repeatability.

Compact Design: Often features a compact and ergonomic design, making galvo laser welding suitable for various manufacturing environments.

Real-Time Monitoring: Incorporates real-time monitoring systems to ensure quality control during the galvo laser welding process.

User-Friendly Interface: Equipped with an intuitive user interface, making laser welding galvo accessible for operators with varying levels of expertise.

Advantages of Galvo Laser Welding System

High Precision: Delivers exceptionally precise welds due to the accurate positioning of the laser beam by galvanometer-based scanning systems.

Speed and Efficiency: Enables high-speed welding processes, significantly reducing galvo laser welding processing time and increasing overall efficiency.

Versatility in Material Compatibility: Suitable for welding a diverse range of materials, including metals, alloys, and plastics, offering versatility in manufacturing applications.

Reduced Heat-Affected Zone: Minimizes the heat-affected zone (HAZ) during welding, preserving the integrity of the material and minimizing post-processing requirements.

Automation and Programmability: Supports automated galvo laser welding processes with programmable settings, ensuring consistency and repeatability in production.

Compact and Ergonomic Design: Often features a compact design, allowing for easy integration into manufacturing setups while maintaining user-friendly ergonomics.

Real-Time Monitoring and Quality Control: Incorporates real-time monitoring systems to detect and address issues during the galvo laser welding process, ensuring consistent quality.