Stainless Steel Tube Mill Line

Cur síos ar an Táirge

STAINLESS STEEL TUBE MILL LINE

Stainless still tube mill Line is specially used for producing stainless steel straight seam welded pipe. It is made of refined materials in high precision and equipped with fixed length cutting saw. The main machine includes forming, welding, sizing, and straightening device. The composition of equipment is from decoiler to the run-out table. The rolling speed of our stainless steel tube mill can be adjusted correspondingly within a suitable range of pipe diameter and wall thickness.

Main Components of stainless steel tube mills

1.1 Decoiler:

Double-side 360ºrotary, which ensures steel coil feeding alternatively and makes steel strip going into accumulator freely.

1.2 Shearing and butt-welding machine

It ensures tide double steel coil shearing and weld seam leveling.

1.3Forming, welding, and sizing unit

(1)Feeding & leveling device:

Form: Up and down rolls are passively leveled for straightening strip steel before it is fed into forming unit.

(2)Forming device:

Mainly roughly mill-forming steel strip and controlling weld seam.

(3)Guiding extruding and welding scraping apparatus:

a. One set of guide roll stand for controlling the direction of pipe seam to insure pipe seam flatly and straightly entering into extruding rollers.

b. Two sets of extruding roll stand for controlling weld seam to realize successful welding.

c. Two sets of scraper frame for scraping outside weld seam

(4)Sizing device: Mainly fine shaping pipe after welding and controlling size accuracy.

(5)Roughly straightening machine frame

It is mainly used for roughly straightening of the finished pipe.

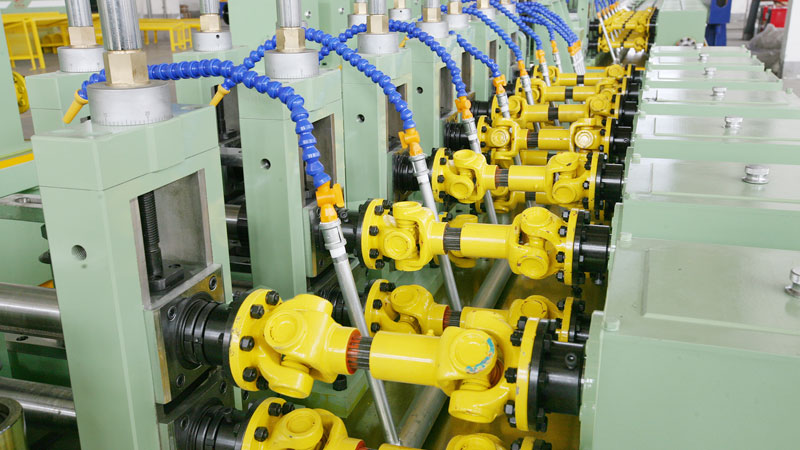

(6) Main driving system: The main unit is connected with the main reducer by the main motor and transmits power to gearbox branches, then gearbox branches drive upper and down shafts on horizontal roll frame.

Technical Parameters of Stainless Steel Tube Mill Line

Model Diameter Thickness Speed Dimension

mm mm m/min Length*Width(m)

RFT-SS25 Ф5-Ф25 0.25-0.8 1-8 19.5*1

RFT-SS32 Ф10-Ф32 0.3-1.5 1-8 20*1

RFT-SS38 Ф12-Ф38 0.4-2.0 0.5-6 20*1

RFT-SS50 Ф16-Ф50 0.6-3.0 0.4-5 21.5*1.1

RFT-SS76 Ф25-Ф76 1.0-3.5 0.4-4 22*1.2

RFT-SS80 Ф32-Ф80 1.5-5.0 0.3-3 24*1.2

RFT-SS114 Ф50-Ф114 1.5-6.0 0.3-3 26*1.4

RFT-SS168 Ф76-Ф168 1.5-8.0 0.3-3 32*2.3

RFT-SS219 Ф114-Ф219 2.0-10.0 0.2-2 36*2.5

Finished Tubes by Stainless Tube Mills

Application Of Stainless Steel Pipes

You can locate the existence of stainless steel pipes on various occasions. With the help of our stainless tube mills, you can easily manufacture high-quality stainless steel pipes for construction, oil and gas processing, chemical application, food processing, etc. As a professional stainless steel tube mill manufacturer, Hangzhou Roll Forming Technology can help you to start your own stainless steel pipe business.

As one of the most professional tube mill rollers supplier, we provide roll forming equipment, coil upender, welded tube mill line, steel pipe mill, tube mill machine and etc. For more information about roll forming tube , please feel free to contact us!