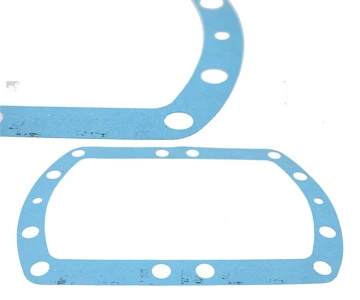

Gasket Seals

Апісанне тавару

Gasket seals are used in the hydraulic system, engine, transmission, and cooling system of excavators to prevent the leakage of liquids (such as hydraulic oil and coolant) and gases (such as combustion gases and compressed air).

Gasket Seals Role

Gasket seals play a crucial role in various mechanical and industrial applications by providing a reliable seal between two mating surfaces. Their primary function is to prevent the leakage of fluids (liquids or gases) and to maintain pressure within a system. Here are some key roles of gasket seals:

Leak Prevention: rubber gasket seals fill the microscopic gaps and irregularities between mating surfaces, ensuring that no fluids escape from the system. This is essential in applications like engines, pipelines, and pumps.

Pressure Maintenance: By creating a tight seal, gaskets help maintain the required pressure within a system, which is vital for the efficient operation of hydraulic and pneumatic systems.

Vibration Dampening: Gaskets can absorb vibrations and shocks, reducing the risk of damage to the components they are sealing. This is particularly important in automotive and heavy machinery applications.

Chemical Resistance: Gaskets are often made from materials that can withstand exposure to various chemicals, ensuring long-term durability and performance in harsh environments.

Thermal Insulation: In high-temperature applications, gaskets can provide thermal insulation, protecting sensitive components from heat damage.

Electrical Insulation: Some gaskets also offer electrical insulation properties, preventing electrical currents from passing between components.

Overall, gasket seals are essential for ensuring the integrity, efficiency, and safety of mechanical systems across a wide range of industries.

Rubber Gasket Meaning

Gaskets, often used with O-rings, play a crucial role in securing excavator parts and enhancing performance.

Gaskets are small, but they can become a tight connection hub between excavator parts, which shows their great role, gaskets can fill the gap between objects. Most of the time with the O-ring used together. The main role of the O-ring is to enhance the compressive strength, to prevent extrusion, easy to install, tensile strength, good resilience, good resistance to extrusion, the size is not easy to deformation. Material selectivity, according to the need to purchase, PTFE, PTFE + copper powder, nylon, nylon + copper powder, there are TPU, the quality of the price can be given to the best, the choice of a good gasket, you can improve the efficiency of the excavator and reduce the cost of maintenance.

Hydraulic Seals Application

As a premier seals supplier, Jiarui offers versatile sealing elements for a multitude of fields. Our products are indispensable in mechanical and equipment engineering, construction engineering, and various other industries. Our seals enhance performance and reliability, tailored to meet the specific needs of each sector. By delivering high-quality, application-focused solutions, we support modern industrial advancements and ensure optimal functionality across diverse engineering applications, fulfilling the varied demands of our customers.

For more information about gasket material and gasket types / types of gasket, please feel free to contact us!

If you are looking for a reliable seals supplier, please contact us.