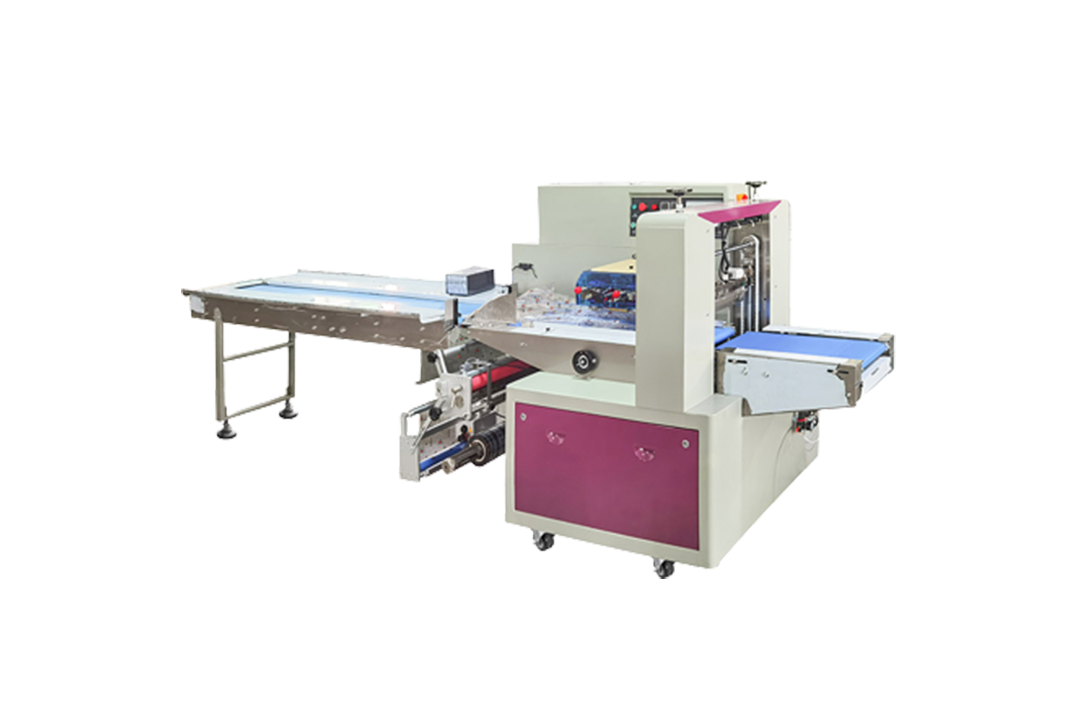

HORIZONTAL FORM FILL SEAL MACHINE

Penerangan produk

The horizontal flow wrap machine is an automatic continuous shrinkage packaging equipment, which is characterized by the fast temperature rise of the sealing knife, good stability, and low maintenance cost. The shrinkage temperature and motor transmission speed of our horizontal form fill seal packaging equipment is stable and adjustable, and the adjustment range is wide. The original roller rotation device can work continuously. As one of the mature horizontal form fill seal machine manufacturers in China, Guonuo can provide you with quality horizontal FFS machine at great prices! Feel free to contact at any time.

TYPES OF HORIZONTAL FORM FILL SEAL MACHINES

Horizontal Form Fill Seal Fruit Packaging Machine

GN-ZB-250B HFFS pillow packaging machine is an entry-level automatic horizontal FFS machine in the form fill flow packaging machine series.

Horizontal FFS Cookie Wrapping Machine

GN-ZB-320D Horizontal Flow Wrapping machine(HFFS)adopts the upper film structure and makes a 3-side pillow pack.

Daily Necessities Hffs Pillow Packing Machine 450X

GN-ZB-450X daily necessities dishwasher and chopsticks flow packaging machine(HFFS)is a fully automatic pillow packaging machine specially designed for the packaging of daily necessities.

Hffs Hardware Pillow Packing Machine 350X

GN-ZB-350XSF pillow packaging machine can accurately and quickly provide the sealing of plastic bags. We can also customize your horizontal form fill seal machine according to the size or length of customers' materials.

HORIZONTAL FORM FILL SEAL MACHINE VIDEO

GN-ZB-320S Pillow type packaging machine can be used for single packaging, or multiple cakes can be stacked together for packaging. The form of the bag is serrated and easy to tear, which is basically in line with the packaging mode of cake food commonly seen in the market. The pillow packing machine is controlled by a double frequency converter, which has good equipment stability, low noise, fastpacking speed, higher yield, and packaging aesthetics.

Workflow of the horizontal form fill seal machine: the operator manually stacks a single cake or multiple cakes together and puts them into the conveyor belt of the packaging machine. The cake is sent to the packaging machine for packaging through the conveyor belt. The packaging process is completed through film rolling, cutting, and finished product output. Easy to operate and multi-purpose, our horizontal form fill and seal machine are suitable for soft, strip, and unorganized objects such as towels, paper towels, noodles, egg rolls, sausages, fish, popsicles, soft candy, fresh fruits, and fresh vegetables.

HORIZONTAL FORM FILL SEAL MACHINE ADVANTAGES

Controlled by a dual-frequency converter, the bag length of our horizontal form fill seal machine can be set and cut immediately without adjusting the empty walk. It can be achieved in one step, saving time and film.

Human-machine interface, convenient and fast parameter setting.

The fault self-diagnosis function and the fault display are clear at a glance.

High sensitivity photoelectric eye color mark tracking and digital input of sealing and cutting position to make the sealing and cutting position more accurate.

Independent PID control of temperature is better suitable for various packaging materials.

Positioning shutdown function, without sticking knife and wasting coating.

The transmission system of the horizontal form fill and seal machine series is simple. Its work is more reliable and the maintenance is more convenient.

If you are looking for a reliable packing machine company, don't hesitate to contact us!