Electronics Mold

Opis izdelka

Consumer electronics is very popular in our daily life. It consists of many different plastic parts, pcb boards, wires, battery and some metal parts. To produce the plastic components of consumer electronics, we need manufacture the plastic injection molds first.

Consumer electronics mold require high accuracy, good assembly effects and high grade appearance. Design of injection molding electronics is the first step and basic factor to manufacture high quality injection mold. State of art mold processing equipment is essential. Green Vitality Industry have 25sets all kinds of advanced mold processing equipment, which ensures our injection mold high precision and fast delivery.

Plastic Molding Electrical

Keyboard Mould

Green Vitality is professional in making plastic injection mold and have 25years experience. As an reliable injection mold manufacturer and exporter, consumer electronics mold is also one of our areas of focus.

Mouse Mold

Computer mouse plastic injection mold belongs to consumer electronic mold. It's used to produce computer mouse.

Game Controller Mold

Gamepad mold enriches our sparetime lives. One complete gamepad is usually made of different plastic injection parts. So we need make several injection molds. After all gamepad molds finished, then comes to the plastic parts injection production.

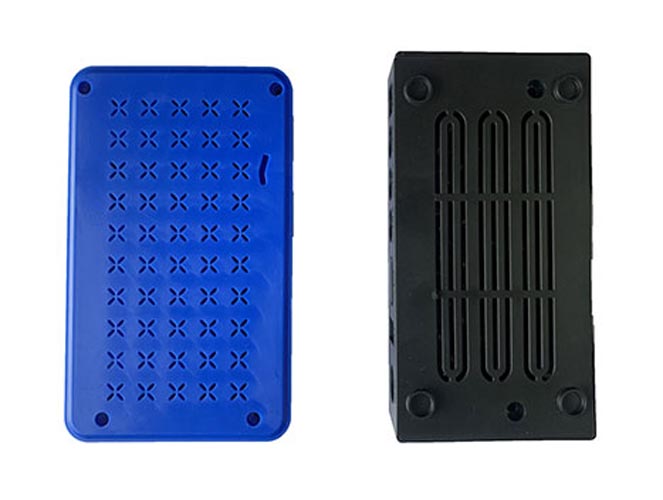

Plastic Enclosure Mold For Electronic Device

The electronics enclosure plastic part was designed for a Media project for 20 Lego Discovery Centers around the world. The plastic injection mold we made is the shell of a handheld laser product.

Set Top Box Plastic Injection Mold

We have made series of set-top box shell molds. Generally the material of the set top box cover is ABS, which is also a kind of plastic material commonly used to make shell products.

Precision of Injection Molding Electronics Industry

For consumer electronics mold, precision is an important thing for mold supplier and the customer. How to secure the precision of consumer electronics molds? We can start from the following points.

ADVANCED AND UPDATED CONSTANTLY

The processing equipment must be advanced and updated constantly. Advanced equipment is the fundation to build a high precision mold. So for a modern manufacturing company, they must invest state of art high technological equipments. Green Vitality Industry insists science and technology as the first productivity, bring in sophisticated equipment to meet the high quality requirements of the market and customers.

HIGH TECHNICAL LEVEL

The level of mold processing technicians must be high. They must be experienced, professional and skillful. Green Vitality recruits highly skilled and responsible technicians, give them regular training to improve their professional skills and level. Sometimes we convence meetings to listen their opinions and discuss the best way to process the molds, this decreases mistakes greatly and save much time and energy on correction.

HIGH ACCURATE INJECTION MOLDING PARTS

The actual surface size, shape, position of a part after injection molding to which three kinds of geometric parameters must accord with the ideal geometric parameters required by the drawing. The machining accuracy is measured by tolerance grade. The smaller the grade value, the higher the accuracy. The machining tolerance is marked by numerical value, the greater the numerical value, the greater the tolerance. A high precision mold will create a small tolerance injection parts. So we need well control the tolerance to get high accurate injection molding parts.

01

ADVANCED AND UPDATED CONSTANTLY

02

HIGH TECHNICAL LEVEL

03

HIGH ACCURATE INJECTION MOLDING PARTS

The Production Control of Electronics Mold

Material temperature control

Different raw materials have corresponding temperature requirements, if the fluidity of raw material is poor, then the temperature should be raised, to control the flow value in the best range.