Auto Part Mold

توضیحات محصول

With the vigorous development of the automotive industry, plastic auto part mold is also developing rapidly. 90% of auto parts are produced by injection molds, which is a huge market opportunity for auto plastic parts manufacturers .

Common large-size auto parts such as car bumpers, fenders, hoods, grilles, doors, rear seats, front covers, and other parts require large-size injection molds. This will require auto plastic mould parts manufacturers to invest in large machines. For some Automobile parts with complex surfaces, high-speed and high-precision CNC machining is required.

Types of Car Part Mold

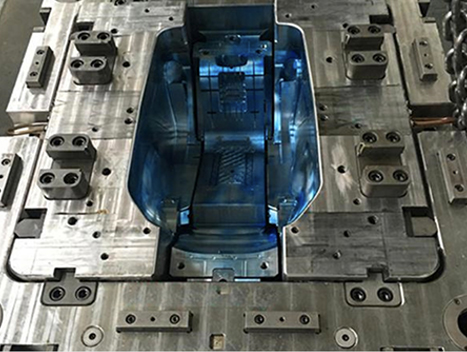

Car Seat Mould for Kids

Baby car seat mold affects the plastic car safety seat molding production output a lot. A high efficient cooling system for the plastic car safety seat mold will shorten the shot circle, as a result, save more machining costs and time. JMT concerns a lot about mold cooling systems and production stability. Our aim is to make customers run molds as little as possible for mold repair work, the best is free of repair work during mass production.

CUSTOM PLASTIC INJECTION MOLD

Auto Rear View Mirror Housing Mold

Green Vitality Industry supplies automotive rearview shell plastic injection mold since 2013. We can provide you with Innovative solutions, speedy and speedy, and precise design & analysis, high quality, and longevity on your project.

CUSTOM PLASTIC INJECTION MOLD

Car Light Mould

For cars, lamps are an essential function. The most important part of the lamp is the headlamp body, reflector, decorative frame, and lamp mirror. Green Vitality provides car lamp cover mold design and manufacturing solutions.

CUSTOM PLASTIC INJECTION MOLD

Automotive Air Grille Mold

The car grille is a mesh part of the front of the car. It is a very important part of auto parts. It has the functions of decoration, protection, and ventilation. Green Vitality is an experienced on making kinds of automotive parts molds, especially in plastic car air grill mold.

CUSTOM PLASTIC INJECTION MOLD

Auto Bumper Mould

Automobile bumpers are made of plastic materials, which not only have decorative functions but also have devices for absorbing and buffering shocks and protecting the body and the driver. Green Vitality specializes in bumper making, bumper molding, car bumper manufacturing process.

Process of automotive injection molding

In order to effectively control the development cost of mold building, reduce the cost of later repair molds, accelerate the progress of product development, and fully verify product performance as much as possible. In the mold development process, auto part verification needs to be carried out in several stages.

PROTOTYPE SAMPLE

Usually made by rapid prototyping parts, CNC processed rapid prototypes, prototype sample is used for dimensions and assembly verification. The dimensional accuracy of the prototype sample is high, and the production cycle is fast, usually within 1 week.

SOFT TOOLING

After quick sample verification, after changing the problems found, a small displacement trial assembly verification will be carried out as verification before the formal plan. To carry out a more adequate verification and avoid the risk of mold scrapping, usually at this stage, lower-cost soft tooling is developed first, and the material and structure of the parts are consistent with the mass-produced parts. The development cycle of steel molds is usually long, with small parts within 1 month, and large parts even require more than 4 months of development time. Soft molds can usually produce no more than 10,000 shots.

PRODUCTION TOOLING

After the parts have been fully verified and approved, the official steel mold is developed. The official steel mold can produce 50000, 100000, or 300000 parts according to the different steel materials used, and select the appropriate steel material according to the planned output.