Types of PCB Capabilities

Produktbeskrivelse

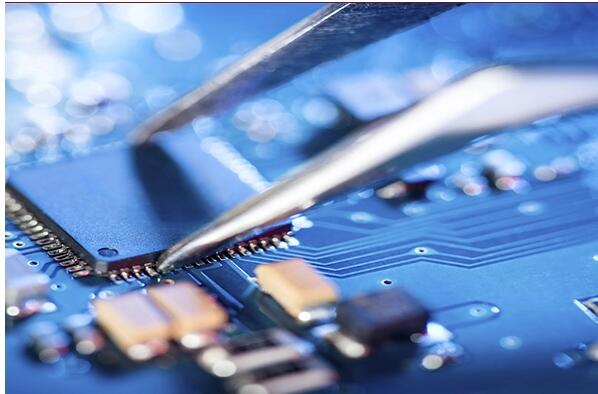

PCB (printed circuit board) capabilities refer to the technology and processes that are used to manufacture printed circuit boards. This includes processes such as subtractive and additive manufacturing, etching, drilling, plating, and surface mount technology. Additionally, it includes the ability to fabricate PCBs with different materials and layers, as well as the ability to add components and embed components such as microchips. PCB capabilities have become increasingly advanced over the years, allowing for the production of more complex and efficient PCBs. Such advancements have enabled the development of a wide range of electronic devices and components, from smartphones to medical devices.

Advantages of Our pcb fabrication capabilities

The advantages of pcb manufacturing capabilities are numerous.

Firstly, PCBs can be designed to be incredibly compact and lightweight, making them ideal for use in high-precision systems or in areas where space is limited.

Secondly, PCBs can be designed to be highly reliable, with accurate components and well-constructed boards that can withstand harsh environmental conditions.

Thirdly, PCBs can be designed to optimize performance, such as by using high-performance components and signal routing techniques. Lastly, PCBs can be designed to meet stringent electrical requirements, to ensure that the board meets the required safety and performance standards. Ultimately, PCBs can provide a reliable and efficient platform for a variety of applications.

GT, as an excellent pcb fabrication supplier, offers a wide range of printed circuit board china for you to choose from.