Medical Equipment Mould

مصنوعات کی وضاحت

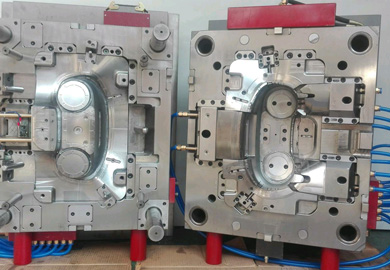

Medical Equipment Mould

Medical device injection molding is a process using medical-grade plastic materials to manufacture different durable medical parts and components. The medical device plastic injection molding process can provide benefits for a variety of applications such as medical enclosures, needles, surgical instruments, prosthetics, and so on.

GM-TECH is one of injection molding manufacturers. Our medical device molding parts and components with relatively low plastic injection molding cost are safe and reliable, which deserves your trust.

Features of Medical Equipment Mould

Due to the high-quality materials, the medical device injection molding process can be performed smoothly and safely, which ensures the medical parts are durable and reliable. These medical-grade plastics have become the ideal material for different kinds of electronic medical equipment. Several features that our medical device plastic injection molding service can provide, include:

Reduced weight

Increased functionality

Lower cost

The decreased burden of sterilization

The Specification of Medical Equipment Mould

Part material ABS

Cavity 1 + 1

Mould accuracy + / - 0.02mm

Mould steel H13

Mouldbase steel 1.173

Mould life 100W

Mould standard DME

Mould structure 1 slides

Exporting country USA

Leadtime 5 weeks

Mould quality customer satisfaction 0.98

FAI pass rate 0.96

Project cooperation service customer satisfaction 0.98

How does Medical Equipment Mould Work?

When it comes to the working principle of medical device molding, it is inevitable to mention the medical process machine. The medical device precision injection molding machine consists of three parts, namely the feed hopper, the screw, and the heated barrel.

When the feed hopper receives the plastic granules, it uses the frictional action of the screw to create heat. Once the plastic reaches the correct temperature, it is then injected into the medical device plastic injection mold cavity. Finally, it gradually keeps cooling and takes the shape of the designed medical device molding part.

If you want to buy high quality plastic moulded products, please contact us.