Injection Molding

제품 설명

Over 20 years in China prototype precision plastic injection mold design services covering a wide range of plastic injection molding technology for electronic, cosmetic, food & medical, household, and industrial products with engineering assistance and an intensive list of secondary operations to customers' custom plastic injection mold and molding process successful.

As an experienced plastic injection tooling manufacturer, we specialize in injection, insert, and over-molding for varieties of plastic products in different industries such as injection molding automotive industry, and plastic injection molding medical industry with sophisticated capabilities and thorough knowledge of precision prototyping and manufacturing offering solutions to manufacturing needs. From prototypes manufacturing to high-volume production, our state-of-the-art equipment and facility give the flexibility to deliver high-quality molded products with quick turnaround times.

Injection Molding Overview

Electronic component

Injection molding service is instrumental in the production of a multitude of electronic parts, from tiny components in your smartphone to larger parts in home appliances, offering precision and consistency on a mass scale.

Houshold product

From kitchen utensils to children's toys, injection molding facilitates the creation of durable and cost-effective goods that enhance our everyday living experience.

Electronic products with over mold

These are products that require an additional layer of material over the original part, providing added functionality, such as shock absorption, grip, or aesthetic appeal.

In the medical field, injection molding proves to be invaluable. It aids in the production of a variety of medical products, from surgical instruments to implantable devices, adhering to stringent quality and hygiene standards.

Precision injection molding is used to manufacture a wide range of products, from automotive parts to construction materials, showcasing its versatility and efficiency.

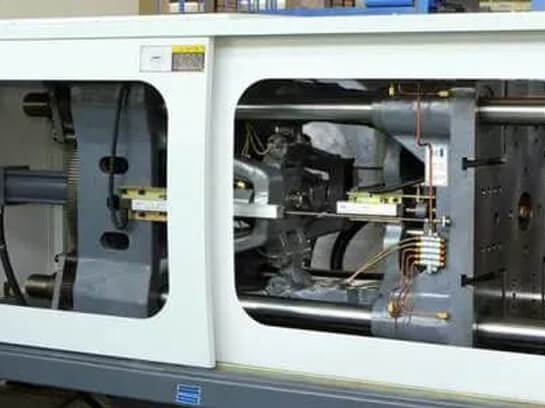

How Does Injection Molding Work?

Injection molding is a manufacturing process used to produce parts in large volumes. It is most commonly used in mass-production processes where the same part is being created thousands or even millions of times in succession.

Here's how it works:

Material Selection: The process begins with the selection of a material, which is typically in the form of small pellets. The material is chosen based on the specific requirements of the part being produced.

Melting: The pellets are fed into the precision injection molding machine and pushed towards the mold by the injection unit. During this process, the material is melted by heat and pressure. The plastic is heated until it is molten.

Injection: The molten plastic is then injected into the mold at high pressure. The mold is a custom design that corresponds to the shape of the desired part.

Cooling: Once the plastic is inside the mold, it begins to cool and solidify into the shape of the desired part.

Ejection: After the part has cooled, it is ejected from the mold. The mold then closes again and the process begins again.

Trimming and Inspection: Any excess plastic that remains after the part has been ejected is trimmed off. The parts are then inspected to ensure they meet the required specifications.

This process allows for high levels of accuracy and can be used to create complex and intricate parts. It is also highly efficient, making it a popular choice for mass production.

Injection Molding Advantages

Injection molding has several advantages, including:

High Production Speed: Injection molding machines can produce high volumes of the same object quickly, making it ideal for mass production.

Precision: Injection molding can produce complex and intricate parts with a high level of accuracy and consistency.

Low Labor Costs: The process is largely automated, which can significantly reduce labor costs.