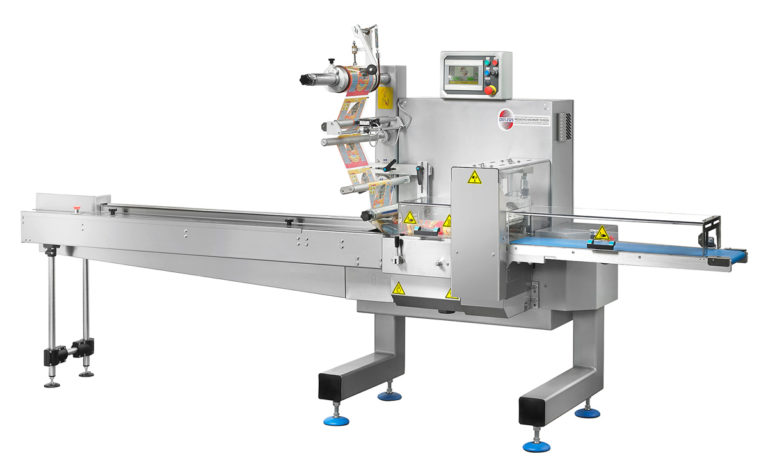

Auriga 500E – Basic Flow Wrap

Описание товара

Main machine structure in painted steel RAL 9006 and stainless steel AISI 304 guards;

Cantilever machine execution with mechanical transmissions positioned behind machine separated and isolated from working surface and protected from dirt and product residues;

Integrated Electrical system and protected within the machine frame;

2100mm length infeed conveyor with removable plastic pushers (usable loading space 1400mm approx.) complete with stainless steel AISI 304 deck plates and side guards (upon request longer or shorter execution are available);

Fast-easy extraction food-grade nylon pushers and pushers supports;

Longitudinal fin seal assembly consisting of : 1° set film pulling cold wheels Ø 120 mm, 2° set film sealing hot fin wheels Ø 120 mm.

One up-rotary sealing unit equipped with an 240mm width jaw, with transversal or longitudinal sealing pattern and complete with inclined cutting knife assembly (standard sealing width 12,5 mm) (upon request multi-jaws crimper available);

Electronic torque limiter on transverse sealing jaws;

Discharge conveyor having a length of 800 mm;

Motorization by means of 3 stand-alone brushless servo motors: one for the infeed conveyor, one for fin wheels assembly and one for transversal jaws assembly;

Mechanical transmission with toothed belts maintenance-free;

Planetary gearboxes with no need to be lubricated.

Upper one self-centering cantilever film reel holder 500mm width;

One meter length discharge conveyor belt, motor-driven independently;

Safety guards transparent shockproof plastic material and safety related micro;

Color touch screen 7 “. Storage of up to 99 work programs.;

One adjustable or fixed forming box;

Machine direction from left to right as shown on general catalog;

Machine built in accordance with CE standards