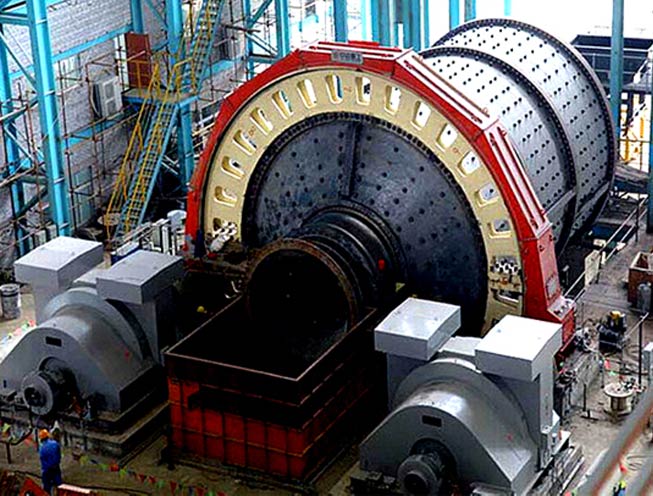

Wet Grid Ball Mill

Описание товара

Wet ball mill is a kind of energy-saving industrial ball mill which adopts rolling bearings and has high efficiency. Wet grid mining ball mill processing capacity can reach 160 tons per hour. It usually grinds coarser ores.

Instruction of Wet Ball Mill

The operating environment of the wet grate overflow ball mill is to treat the pulp with high water content, and the pulp concentration is between 30% and 50%. Wet ball mill is arranged at the end of the ore row grid, ball grinding machine can be forced to row ore, so wet grid type ball mill in a variety of open or closed circuit occasions, ball mill mining is used for coarse-grained mineral grinding; wet ball mill can also be used for one stage grinding or one of two stages grinding. Because the lattice type is forced ore discharge, so the grinding time of material in the shell is relatively short and the discharge particle size is relatively coarse, which is generally 0.2-0.3mm, it suitable for the primary grinding stage. Compared with overflow ball mill, wet ball mill can better avoid the problem of over-grinding.

Structure of Wet Ball Mill

The working principle of wet ball mill is to make it rotate slowly through the transmission device, and the material is fed into the feeding end of the shell. The material in the shell is crushed due to the drop impact and self-grinding of the steel ball and the ore itself. As the material is constantly fed, the pressure makes the material in the shell move from the feeding end to the discharging end. The material reaching the finished product size is discharged from the discharging end. When wet grinding, the material is taken out by the current; In dry grinding, the material is taken out by air flow. There is the grate in the discharging end of horizontal ball mill, the ball mill discharge ore by the grid plate, pulp surface in the shell is low, reduce the ore over grinding, and prevent the discharge of the steel ball.

Advantage of Wet Ball Mill

Wet ball mill adopts large double-row self-aligning roller bearings, which is easy to start while reducing friction and can save about 20%-30% energy.

Wet ball mill adopts wavy ball mill liner replacement, which enlarge the contact surface of the ball ore, effectively strengthens the grinding effect, it has a lifting effect on the ore, and reduces the consumption.