DOUBLE SIDED SCRIM TAPE

รายละเอียดของสินค้า

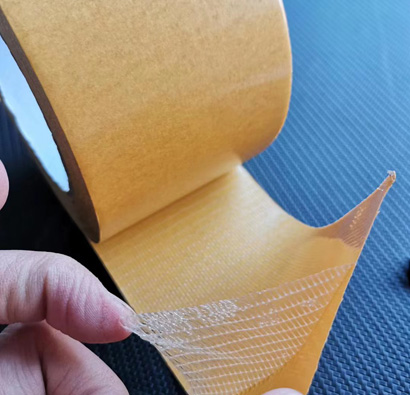

DOUBLE SIDED SCRIM TAPE

Double sided scrim tape is made of high strength glass fiber yarn for strengthening the back material, coated with strong adhesion pressure sensitive adhesive on both sides; The double-sided scrim tape has high tension strength, strong viscosity, high wear resistance and moisture resistance. There is a thin layer of high temperature resistant glass fiber mesh cloth in the middle of the adhesive layer (glass fiber in a very wide range of temperature to maintain dimensional stability very little deformation) can provide vertical and horizontal two-way stable size without deformation. Adhesive materials range is very wide, including rubber, PP/PE, PBT/PET, ABS, PMMA, general plastics, metals, inorganic glass and so on. The adhesive can be maintained in a wide temperature range (temperature range depends on the nature of the adhesive material and the weight of the load).

Double Sided Scrim Specifications

scrim glass tape

Scrim Glass Tape Characteristics Performance Data Test Method

Backing color Transparent Visual

Total Thickness 200 microns (8.0 mil) PSTC-133/ASTM D3652

180° Peel Adhesion ≥25 N/25mm (90.0 Oz/In) PSTC-101/ASTM D3330

Glue Type Water based acrylic

Static Shear ≥48 hrs GB/T4851-2014

Tensile Strength ≥50 N/25mm (13.6 Lb/In) PSTC-131/ASTM D3759

Elongation at Break 9.00% PSTC-6/ASTM D3121

Material PES/PVS diagonal scrim

Features of Double Sided Scrim Tape

Use high duty fiber glass(PES/PVS) mesh cloth as backing

Both sides coated with aggressive pressure sensitive adhesive

Protected by gold glassine paper release liner

Backing material has very good tensile strength

Extremely high adhesion strength

Can be removed with no glue residue & no de-lamination

Excellent resistance to abrasion, moisture, high temperature

Can easily conform to many irregular surfaces

Double Sided Scrim Tape vs Paper Tape

Double Sided Scrim Tape (or Double Sided Fiberglass Tape)

Composition: Double-sided scrim tape typically consists of a strong fiberglass mesh (also known as scrim) embedded between two layers of adhesive. This construction provides excellent strength and durability. Double-coated scrim tape is commonly used in construction and building projects for applications such as mounting, bonding, and sealing. The fiberglass mesh provides reinforcement, making it suitable for heavy-duty applications where strength and stability are crucial.

Key Features of the Double-sided Scrim Glass Tape:

Strong adhesion on both sides.

High tensile strength due to the fiberglass mesh.

Resistant to tearing and stretching.

Suitable for indoor and outdoor use.

Paper Tape

Composition: Paper tape is typically made of paper or a paper-like material with an adhesive coating on one side. It lacks the reinforcement provided by fiberglass mesh. Paper tape is commonly used in painting and drywall applications for tasks such as masking, taping joints, and covering gaps. It is designed to be easily torn by hand and is often used in situations where flexibility and conformability are more important than sheer strength.

Key Features:

Easy to tear by hand.

Flexible and conformable to irregular surfaces.

Suitable for indoor applications where strength requirements are moderate.

Process of Double Sided Scrim Tape Production

NO.1

First, we weave the PES & PVA material diagonal scrim to gridding mesh.

NO.2

Second, we coat on both sides of the backing material with very aggressive water based acrylic or hot melt adhesive.

NO.3

Third, we protect the backing material with kraft paper liner or gold glassine paper release liner.

NO.4

Finally, we use our lathe slitting machines to cut the jumbo rolls to different standard or nonstandard width and length of small rolls. The jumbo size is 1020mmx1000m. In the meantime, we can also rewind to small logs, normally size is 1020mmx50m.