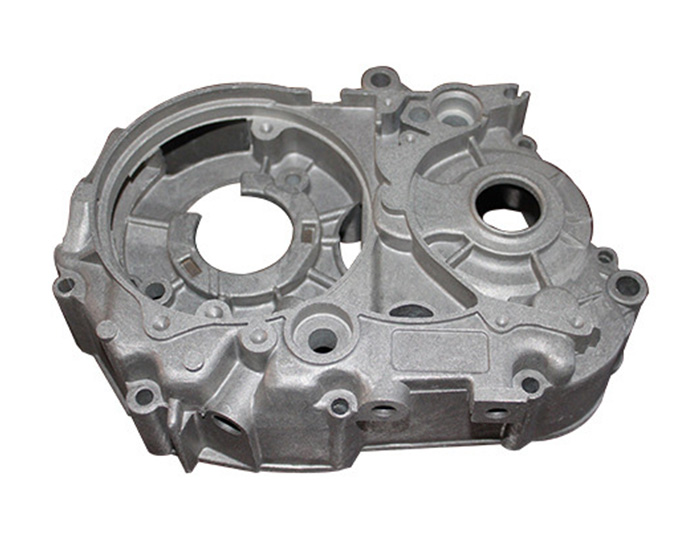

Die-casting aluminum Pump Shell

Tootest

Die-casting aluminum Pump Shell

The pump housing is die-casted. Die-casting is a metal casting process that uses a mold cavity to apply high pressure to the molten metal.

The pump casing is an accessory on the pump body.

Product Introduce:

The pump shell acts as a support and is connected to the bracket on which the bearing is mounted

Aluminum pump housing Feature:

Light weight

Beautiful appearance

Precise size

Excellent wear and corrosion resistance

Improve pump efficiency

Long service life

aluminum pump casing Advantage:

1, The aluminum pump casing is made by injecting aluminum or an aluminum alloy into the mold under pressure. This process is suitable for mass production of parts and at a lower cost.

2, Aluminum castings are a process of injecting aluminum alloy under pressure, which can produce large quantities of parts at low cost, and aluminum die casting is also a process with very high resource utilization.

3, A complete cycle can vary from one second for small components to minutes for a casting of large part, making aluminum die casting the fastest technique available for producing precise aluminum & aluminum alloy parts.

aluminum pump casing Application:

Chemical and petroleum industry, agriculture industry, mining and metallurgy industry, electric power industry, mechanical industry and other fields

More information you can views here

Die-casting aluminum Pump Shell Description:

Technology Die casting

Product name Pump shell

Drawing format CAD, PDF, STP, DWG or sample

Die casting machine type From 160T to 1250T die cast machines

Import / eksport

1.00 Tonn

Franko parras

T/T, L/C, D/P