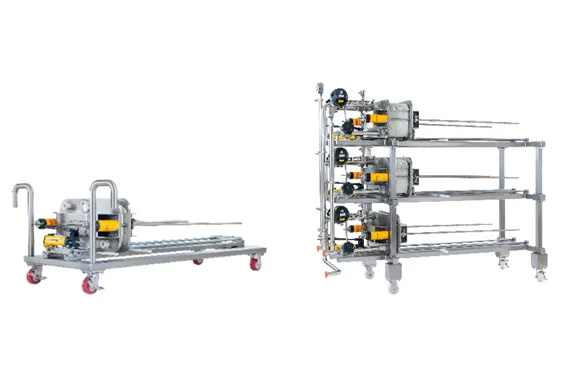

Depth Filtration Bioprocess Fixture Type M

Descripció del producte

The depth filtration system is designed to remove large cell particles in the preparation of biological products, such as cell clar- ification (in bioreactor rooms) or intermediate product filtration (in purification rooms). The system mainly consists of a power unit, a cassette holder, a detection unit, and an automatic control unit.

The depth filter holder is used to hold primary or secondary deep filtration cassettes of a given area. Under the action of a power pump, the feed liquid passes through the cassettes, which intercepts the solid particles in the liquid for clarification. The horizontal design of the holder allows the cassettes to stay leveled in the case of horizontal stacked installation, so as to re- duce residual area and avoid airlocking.

Features of depth filtration in bioprocessing Fixture Type M

Compatible with prevalent square deep filtration cassettes on the market.

Suitable for lab-scale research and development, pilot-scale production, and large-scale production.

Suitable for various primary and secondary clarification and filtration applications.

Works for various materials: cell cultures, yeast and E. coli lysate, folded proteins expressed by E. coli, media, vaccines, plasma proteins, serum, and etc.

The stainless steel offers resistance against the disinfection by acid, alkali, organic solvents, and other disinfectants, meeting the requirements for CIP and cleaning validation.

Easy to install, set up and operate.

Carefully designed, highly performing, technically innovative, energy efficient, safe and reliable, and easy to maintain.

Smooth surface with no dead ends, easy to clean.

Surface polished Ra < 1.2 um, polished part in contact with the product Ra < 0.5 um.

All the parts in direct contact with the feed liquid are made of sanitary materials, such as 316L stainless steel, PTFE, EPDM, and TPE, for which material certificates are available.

The flow directions of fixed tubing are clearly identified.

Adopts cGMP and FDA certified food grade lubricants.

The rack is made of 304 stainless steel, and the parts in contact with the product are made of 316 stainless steel.

The tubings can resist a pressure of up to 6 bar.

Complete set of accessories (available for immediate use by assembling the pressure tubing and pumps).

The position of the movable plate and the distance of the guide rod can be adjusted, so as to properly hold different num- bers of cassettes.

Optional pressure gauge with qualified metering performance and suitable range.

Depth filters can be installed using a hydraulic device, which is convenient, time-saving and labor-saving.

Equipped with fixable steering wheels.

Clamp connection is available with a universal size of TC50 and suitable fittings.

2 feed liquid inlets and 2 feed liquid outlets in each layer; 1 vent hole on both the inlet and outlet sides.

Flexible drip pan for easy collection of waste liquids.