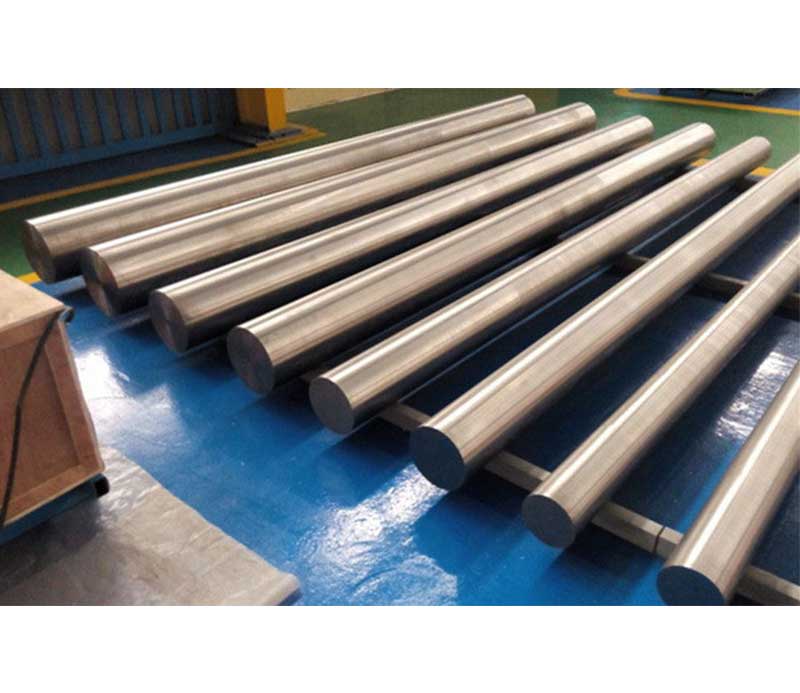

Titanium Rod

Descrição do produto

Titanium Rod

QUICK DETAILS:

Material: pure titanium, titanium alloy

Shape: round, flat, hexagonal

Processing method: forged, rolled, machined

Standard: ASTM B348, ASME SB348, ASTM F67, ASTM F136, ISO5832

Grade on pure titanium: Gr1, Gr2, Gr3, Gr4

Grade on titanium alloy: Gr5, Gr6, Gr7, Gr9, Gr11, Gr12, Gr23

Diameter: 3-200mm

Length: 100-3000mm

GS-METAL Additional information: diameter tolerance and bar length dimensions are based on customer requirements.If you have specific requirements, please let us know and we will ensure that the titanium supplied meets your expectations.

Titanium alloy bar factory:Baoji Guangsheng Metal Matericals Co.,Ltd.Our product include:PVD Sputtering Target, Titanium Bar, Titanium rods, Titanium Sheet, Titanium plate, Titanium Wire, Titanium Elbows, Titanium Flanges and Titanium forgings.

Features Of Titanium Grades:

UNALLOYED TITANIUM

Unalloyed titanium typically contains between 99%-99.5% titanium, with the balance being made up of iron and the interstitial impurity elements hydrogen, nitrogen, carbon, and oxygen. The microstructure of unalloyed titanium consists of grains of alpha phase, with the possibility of small amounts of beta phase. The grades of titanium are generally less expensive, and are easier to fabricate than alloyed, and generally stronger grades of titanium.

ALPHA AND NEAR-ALPHA ALLOYS

Titanium alloys have a fully alpha structure only if they contain alpha stabilizers such as aluminum, tin, and oxygen. These elements also act as solid solution strengtheners. The typical all-alpha alloy is Ti-5Al-2.5Sn. Near-alpha alloys include Ti-8Al-1Mo-1V, Ti-6Al-2Sn-4Zr- 2Mo.

ALPHA-PLUS BETA ALLOYS

These alloys contain both alpha stabilizers and beta stabilizers. These alloys can be heat treated to develop a range of microstructures. The alpha-beta alloys are moderately heat treatable and weldable, while the alpha-beta alloys have greater hardenability, and thus can be through-hardened in thicker section by heat treatment, but are more difficult to weld. The most important alloy is Ti-6Al-4V. The alloys include Ti-6Al-6V-2Sn and Ti-6Al-2Sn- 4Zr-6Mo.

BETA ALLOYS

Beta alloys contain a balance of beta stabilizers to alpha stabilizers, which is sufficiently high that a fully beta phase microstructure can be retained on cooling. Their generally high strength, high toughness, and improved formability, as compared with alpha-beta alloys, provides an attractive combination of properties. However, processing and material costs are often quite high. Ti-3Al-8V-6Cr-4Zr-4Mo is an example of a commonly utilized beta alloy.

Titanium Grade 1: UNS R50250 (ASTM B265 / ASTM B337 / ASTM B338 / ASTM B348)

Commercially Pure Grade 1 is one of the softest and most ductile grades exhibiting the greatest formability. It has excellent corrosion resistance property and is used in wide variety of applications. This grade material is mainly used in Marine & chemical industries where the parts are subjected to very harsh environments. This material is also used for fabricating anodes for cathodic protection applications.

Titanium Grade 2: UNS R50400 (AMS 4902 /AMS 4941/ AMS 4942 /ASTM B265 /ASTM B337 /ASTM B338 /ASTM B348 )

ASTM B348 Grade 2

Grade: Commercially Pure Grade 2

Product Forms: Titanium and Titanium Alloy Bars and Billets

Please note, the ASTM B348 specification covers various Alloys. This Spec Sheet is only for the Alloy listed above.

Composition Analysis

Iron (Maximum): 0.30% Hydrogen (Maximum): 0.015%

Oxygen (Maximum): 0.25% Other Elements (Maximum, Each): 0.10%

Carbon (Maximum): 0.08% Other Elements (Total): 0.40%

Nitrogen (Maximum): 0.03% Titanium: Balance

Tensile Properties (Minimums)*

Tensile: 50 ksi Elongation: 20%

Yield: 40 ksi Reduction of Area: 30%

Commercially Pure Grade 2 is slightly stronger than Grade 1 but equally corrosion resistant against most applications. Grade 2 Extremely high resistance to oxidising or neutral media. Excellent resistance to sea water and solutions polluted by chlorid