Thermal Imaging Camera in Steel Industry

Məhsul təsviri

Metallurgical production-oriented enterprise has a close relationship with temperature, especially the facilities in the enterprise. Any malfunction of the facilities will not only lead to a huge economic loss but can also cause human hurt. So it’s necessary to use the infrared thermal imaging camera to detect the facilities regularly, to learn and master their sate and situation in order to prevent potentially dangerous, ensure safety production operation and prolong the lifetime of the facilities.

A thermal imaging industry camera is a key tool for detecting, controlling, and optimizing metallurgical production processes and equipment. As a reliable, non-contact tool, the camera provides a temperature measurement for the entire surface area rather than several single-point areas. In addition, industrial thermal imaging cameras make it faster, safer, and easier for workers to identify potential problems and avoid sudden system shutdowns and failures.

In the steel industry, industrial thermal imaging camera can be used in every process from smelting to rolling.

1. Thermal Imaging Cameras for Steel Ladle Detection

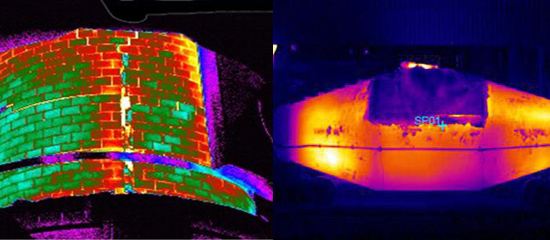

Detect the cracks, bumps, falling-offs of the ladle caused by chemical corrosion, mechanical erosion, and rapid cooling and heating.

2. Thermal Imaging Cameras fir Hot-blast Detection

Use the industrial thermal cameras to detect the hot-blast stove, firstly the body part, then the top part, and pay attention to the joint part of these two parts.

3. Thermal Imaging Cameras for Determination of the surface of large blast furnaces

Modern iron-making blast furnaces require uniform distribution of raw materials added to the furnace, and the distribution of raw materials can be determined from the distribution of temperature at the top surface of the furnace. The infrared camera can detect the temperature by infrared rays in the material surface of the furnace, measure the temperature after image processing, and then control the feed amount by the computer, adjust the flow rate of the raw materials, and distribute the charge reasonably.

ULIRVISION as an excellent thermal imaging company, offers a wide range of infrared thermal cameras for you to choose from.