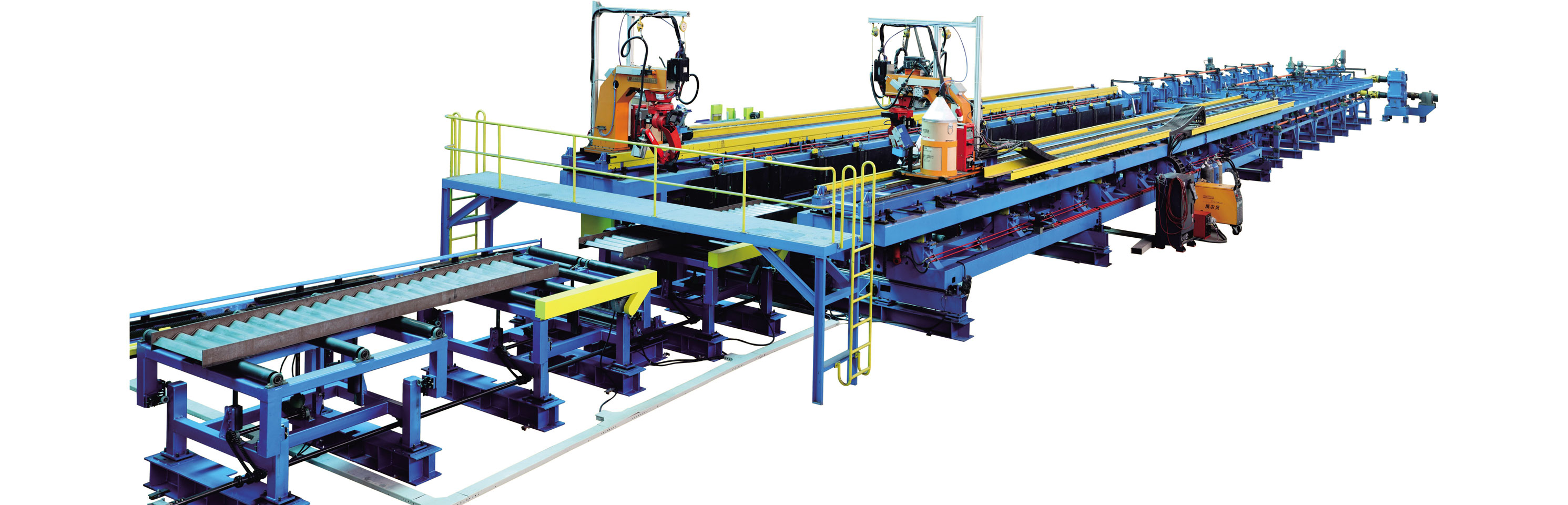

Corrugated Web H-beam Welding Line

مصنوعات کی وضاحت

The corrugated web beam automatic welding machine adopts the welding robot originally from Italy which automatically controls the works such as the whole Line laser scanning, two positions welding, welding gun changing, crosssection cutting and so on. This machine has the features of high quality, high efficiency, full-automation and so on.

It can cut, assemble and weld the tapered beam. The welding speed of this production line is about 700 mm/min (max. projected linear average speed). For the raw materials to feed into the machine, load the suitable coil onto the decoiler or simply feed the flat plate are both OK.

The length, height and thickness the machine can produce:

H-beam length: 4-16 m

H-beam height: 300-1500 mm

Corrugated web thickness: 2-6 mm(≤235 MPa), 2-4 mm(≤345MPa)

H-beam flat web thickness: 4-8 mm

Video of Corrugated Web H-beam Welding Line

Corrugated web H-beam is a new construction materials. It is widely used in bridge, column, single and multiple bay frame construction. The surface is corrugated, and it can save steel 20%~60% under the same yield strength with each beam with flat webs, especially it has high cost performance in large span, crane beam, and so on. The span of 1.5 meters H-beam with corrugated webs can reach 40 meters. The JBH automatic corrugated web H-beam welding line is developed by Zhejiang Jinggong Science and Technology Co., Ltd. The H-beam with corrugated webs use the original binding welding robot from Italy with automatic control to finish the work such as whole line laser scan, two positions welding, changing welding gun, cross-section cutting, and so on.