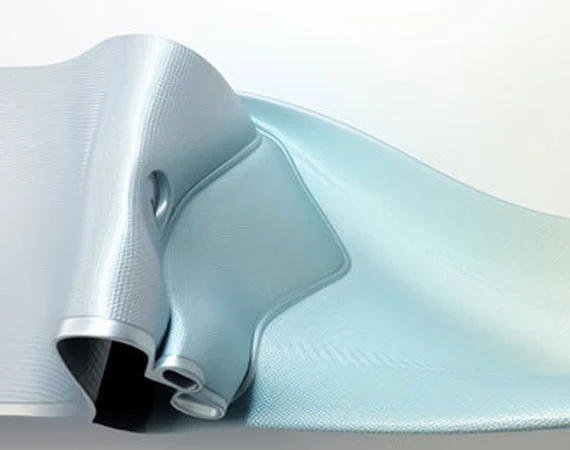

Heat Shields/Exterior Parts

توضیحات محصول

Aftermarket heat shield are crucial components designed to safeguard various parts of a vehicle or machinery from excessive heat, typically generated by engines or exhaust systems. They are usually constructed from metal or other heat-resistant materials, offering high thermal resistance and durability. Their primary function is to reflect and dissipate heat away from sensitive components, preventing damage and ensuring optimal performance.

Exterior Parts of a vehicle, such as body panels, bumpers, and grilles, serve multiple purposes. They contribute to the vehicle’s aesthetics, provide protection against external elements, and enhance aerodynamics. These parts are typically made from durable materials like metal, plastic, or composites, offering corrosion resistance and lightweight properties. They often feature a high-quality finish to maintain the vehicle’s visual appeal and withstand harsh environmental conditions.

Aluminum is the Most Ideal Heat Insulation Material:

(1) Provide high reflectivity and low emissivity, it could absorb and reemit infrared radiation;

(2) Provide high thermal conductivity to ensure heat energy could quickly conduct from the potential hot spot to the aluminum heat shield;

(3) Provide high specific heat capacity. This means that after it absorb a certain amount of heat energy, the temperature rise much lower than many other materials. In the vehicle body, 70% of the thermal management tasks can be handled by aluminum surface alone. The remaining 30% must be handled by the properly designed heat shield.

(4) Provide excellent corrosion resistance. Environmental factors such as humidity and high temperature accelerated the corrosion of the heat shield. In addition, most of the heat shield is directly exposed to road pollution. Pollutants such as brine, liquid asphalt, street dirt and mud. Aluminum will not lead unacceptable heat shield corrosion over the lifetime of vehicle.

(5) Provide adequate fracture resistance. Gravel and slight ground contact may cause local deformation of the lower heat insulation plate. The aluminum structure of the heat insulation cover is not prone to cracking.

(6)Different thicknesses of aluminum plates can be flexibly adapted to meet the various forming and service requirements for heat shields. The airbox heat shield must be as close as possible to the hot source. Space is very limited, especially in the engine compartment and the chassis area, so the car starter heat shield usually has a rather complex shape in order to closely fit the different parts and components.

Features of Heat Shields/Exterior Parts

Heat Shields: These are designed to protect components from excessive heat, often produced by engines or exhaust systems. They are typically made from metal and have high thermal resistance, durability, and reflectivity to deflect heat away.

Exterior Parts: These components, such as body panels, bumpers, and grilles, are designed for aesthetics, protection, and aerodynamics. They are typically made from materials like metal, plastic, or composite materials for durability, corrosion resistance, and lightweight properties. They also often have a high-quality finish for visual appeal.

Applications of Heat Shields/Exterior Parts

Suitable Application Environment and Assembly Site Recommendations:

Thin Aluminum Plate (1060-O): This material is suitable for environments where good heat insulation is required, such as engine compartments, exhaust systems, and other high-temperature areas. It can be used for non-exterior parts that require high heat insulation performance, such as insulation panels, electrical heat shield, and interior components.

There are many sealing product manufacturers, but we are one of the best choices for you.