Spine Glue

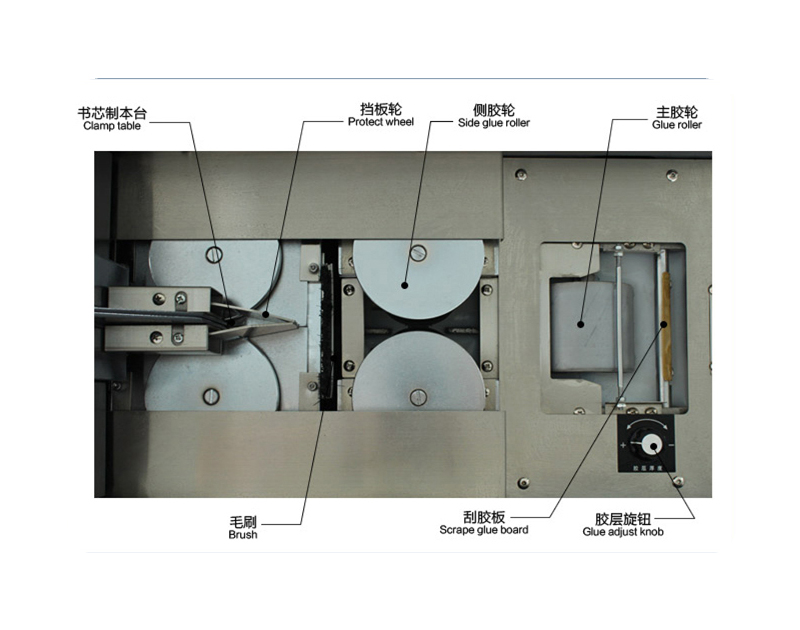

Product description

Spine Glue Products

The spine glue used in book binding have different requirements for the hardness, elongation, breaking strength and permanent deformation rate. The performance requirements of the book binding adhesive are far lower than those of the back glue because the book back is required to be flat and stiff after the book is bound, so the hardness of the back glue used for binding is much greater than that of the spine glue, and the hardness of the back glue is basically 85-90 Shore degrees, And the hardness of the side rubber is generally 75 Shore degrees or less. During the use of the book, the number of pulls and pulls on the back glue is much greater than that of the book cover, which also requires the strength of the back glue to be greater than the strength of the spine glue.

In addition, from the perspective of process factors, the hot melt adhesive glue should be applied first when binding and sometimes jammed paper needs to be glued on the back of the book. If the viscosity of the spine adhesive is too high or the temperature is too high, it is likely that the paper jam or the adhesive has been doubled. Melt and fall off.

Spine Glue Application

TEX YEAR book side glues are characterized by fast setting time, the workability for both fast and slow speed machines; superior bonding on books with hard or OPP laminated covers. We offer high viscosity hot melt adhesive products with stable quality to satisfy customers' demands.

We also can offer peel-able hot melt adhesives for pasting promotional products, such as CD or other small samples, on magazines. Samples would be easily peel-able and no residue on papers.